Gasket Materials - Sheets & Rolls

-

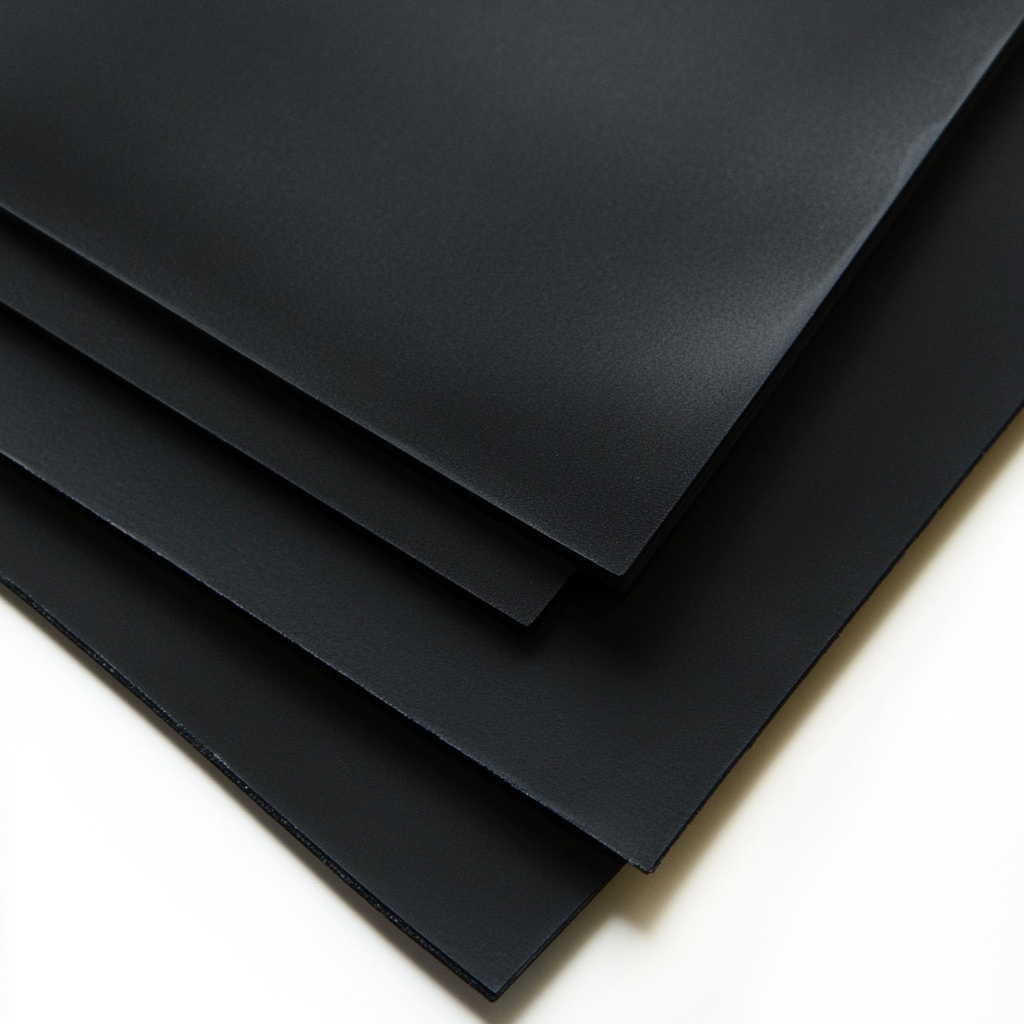

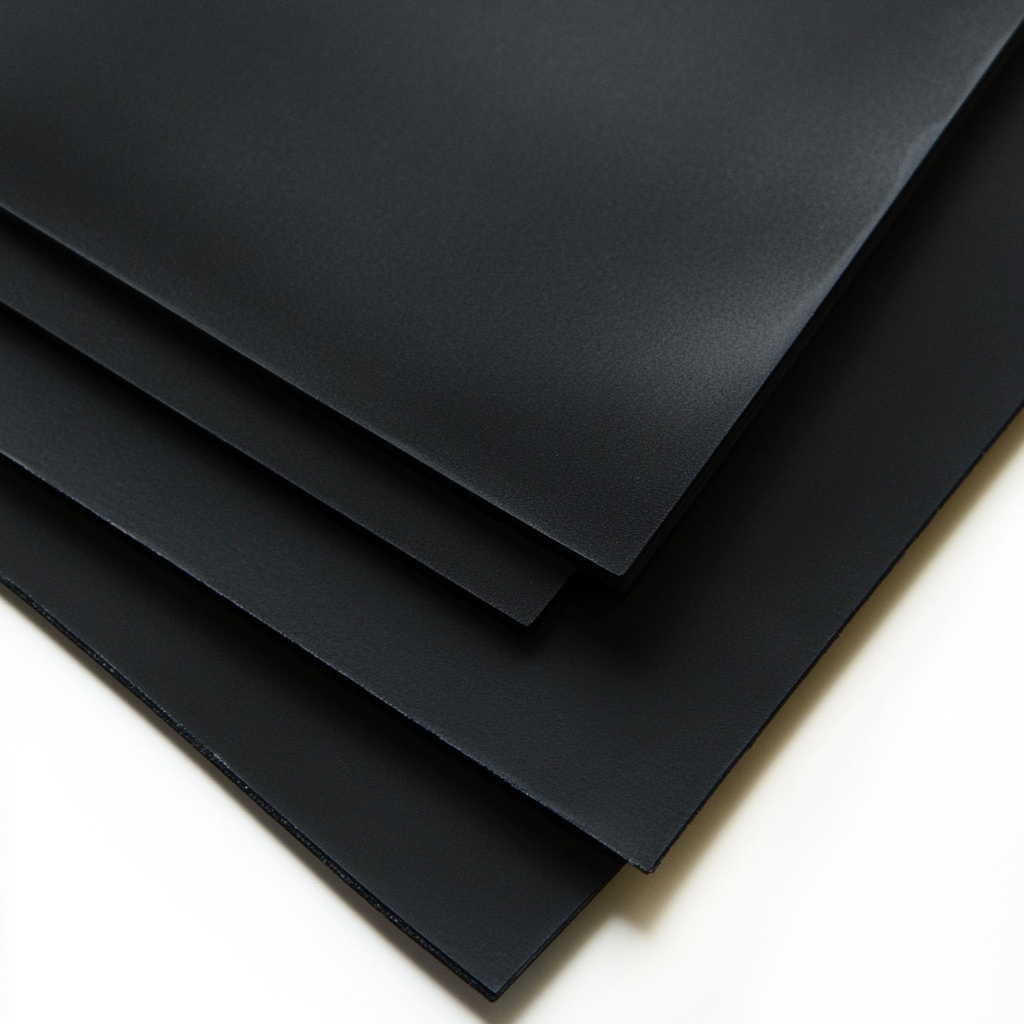

Nitrile Rubber

Nitrile Rubber Our nitrile rubber is formulated for exceptional oil and chemical...

-

Neoprene Rubber

Neoprene Rubber Shop our neoprene rubber designed for various industrial and residential...

-

EPDM Rubber

EPDM Rubber Our EPDM rubber is engineered for exceptional weather resistance and...

-

Viton® Rubber

Viton® Rubber Viton® Rubber Sheets Viton® Fluoroelastomer Premium Viton® rubber sheets now...

-

Food Grade Neoprene

FDA-Approved White Food Grade Neoprene Rubber Sheets Our premium white food grade...

-

PTFE Sheets

PTFE Sheets Our premium PTFE sheets (also known as Teflon sheets) are...

-

Thermo-Super

Thermo-Super Premium Natural Rubber Sheeting Cost-Effective Alternative to Linatex® and Durashield® -...

-

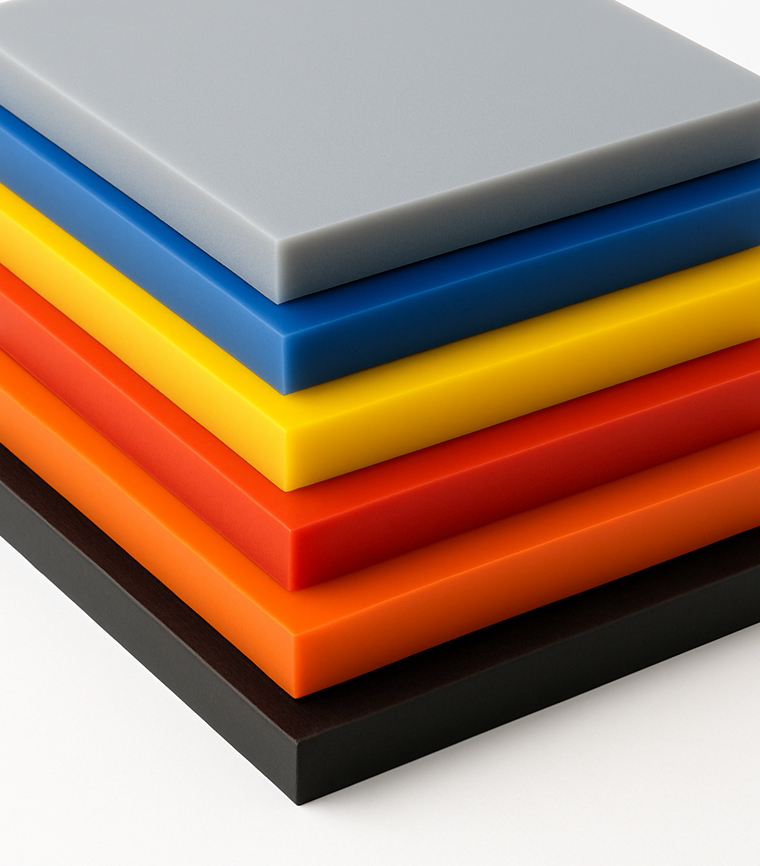

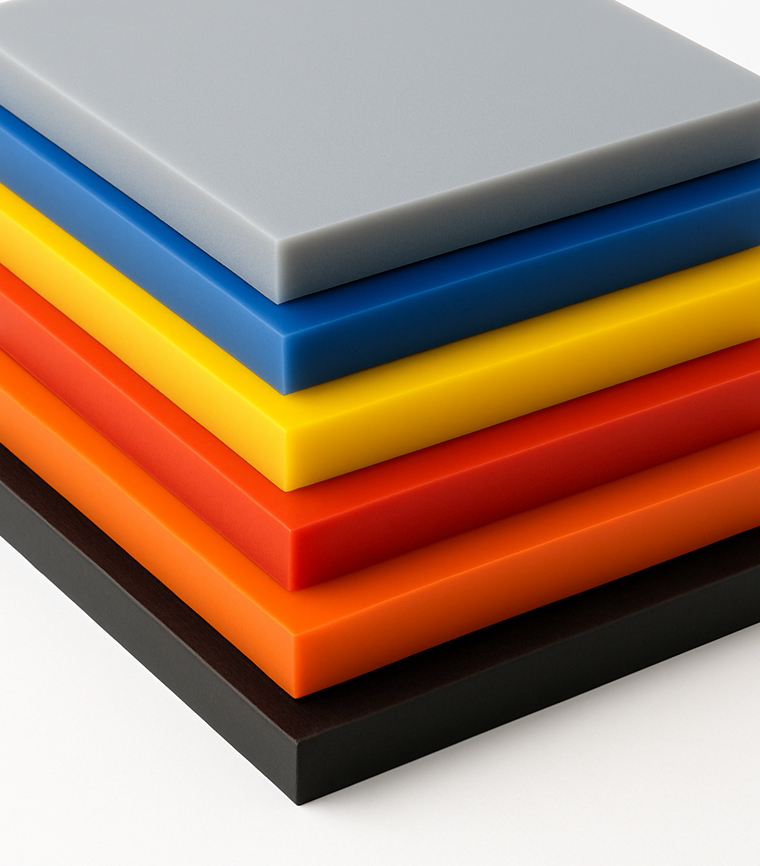

Urethane Sheets

Buy high-quality urethane sheets online. We offer polyurethane sheets in all standard...

-

Services

Learn MoreWith a variety of machines at our disposal – we carefully analyze your project and determine the most effective manufacturing route. Whether you need a rapid prototype, a short production run, OEM production volumes, or a complex custom solution, we deliver high-quality rubber parts that exceed your expectations.

-

Rubber Products

Learn MoreFrom concept to creation, we leverage decades of manufacturing expertise to design, mold, and craft rubber components that perform in the most demanding applications. Our versatility is your competitive advantage.

-

Industries Served

Learn MoreTrusted by leading companies across diverse sectors, Modern Rubber Products engineers rubber solutions that keep critical industries moving. Our adaptable manufacturing capabilities serve everything from automotive to water works and everything in-between.

CUSTOM RUBBER PARTS

Manufacturing Capabilities

Over the past decades, Modern Rubber Products has engineered custom rubber solutions that push the boundaries of manufacturing innovation. Our commitment to precision and adaptability has allowed us to develop a comprehensive range of manufacturing capabilities that transform complex challenges into precisely crafted rubber components. From intricate designs to robust industrial applications, we've built our reputation on delivering custom solutions that meet and exceed the most demanding specifications - no matter the industry.

-

Rubber Molded Products

-

Die-Cut Parts

-

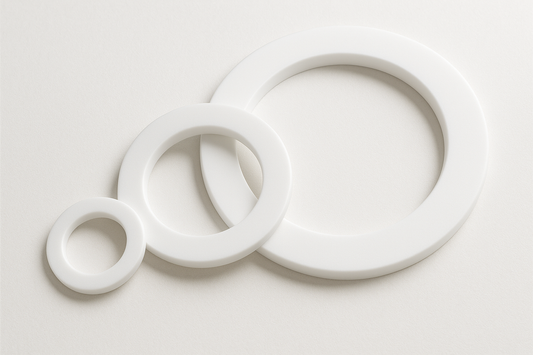

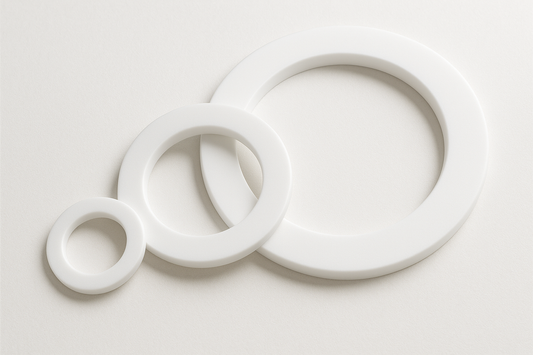

Lathe-Cut Gaskets

Advanced Rubber Molding Solutions

Rubber Injection Molding & Compression Molding

At Modern Rubber Products, our expertise in rubber injection molding sets industry standards for precision and efficiency. Our state-of-the-art injection molding process delivers consistently high-quality molded rubber parts for both high-volume OEM production runs and specialized small-batch requirements.

We excel in processing a comprehensive range of elastomers, including nitrile, neoprene, EPDM, SBR, and NSF 61 grade materials, enabling us to meet diverse industry specifications and performance requirements. Our advanced rubber molding capabilities extend to compression molding, offering you flexibility in choosing the most suitable manufacturing method for your specific application.

A standout feature of our facility is our specialized rubber-to-metal bonding expertise. Our dedicated conveyor line for primer and adhesive application ensures superior metal part preparation, resulting in exceptional bonding strength during the vulcanization process. This capability is particularly valuable for components requiring the durability of metal combined with the versatility of rubber.

Got Rubber Questions?

What makes Modern Rubber Products different from other manufacturers?

Our combination of decades of experience, cutting-edge technology, and a comprehensive range of manufacturing techniques sets us apart. We don't just manufacture – we engineer solutions tailored to your unique challenges and business.

What types of rubber products can you manufacture?

We specialize in custom rubber components across various industries, using advanced manufacturing techniques like injection molding, water jet cutting, CNC knife cutting, and lathe processing. Our capabilities range from small, intricate parts to larger, complex rubber solutions. If it is made from rubber - we can make it.

What materials do you work with?

We work with a wide range of rubber compounds, including natural rubber, synthetic rubber, silicone, EPDM, nitrile, and more. Along with various types of PTFE and compressed fiber material. We have access to Garlock, Klinger, Teadit, Goretex, Parker, etc. Our expertise allows us to select the optimal material for your specific application.

Do you work with small businesses or only large corporations?

We serve businesses of all sizes. Whether you need a small prototype run or large-scale production, Modern Rubber Products is equipped to meet your rubber manufacturing needs.

How quickly can you complete a custom project?

Turnaround times vary depending on project complexity. We pride ourselves on efficient production and can typically provide rapid prototyping and quick-turn manufacturing for many projects. Contact us with your specific requirements for a detailed timeline. We always vow to be transparent upfront on lead times.

Can you help with product design and prototyping?

Absolutely. We offer design consultation and prototyping services. Our team works closely with clients to analyze project requirements, optimize designs, and develop solutions that meet your specific performance and manufacturing needs.

What quality control measures do you have in place?

We maintain rigorous quality control throughout our manufacturing process. Our state-of-the-art optical comparator is a critical tool in our quality assurance workflow, meticulously analyzing every part to ensure precise adherence to specified tolerances and dimensions. By comparing each component against the original part drawing with micron-level accuracy, we guarantee that every rubber product meets exacting standards. We are also committed to continuous improvement, with plans to achieve ISO 9001 certification by 2025. This demonstrates our dedication to implementing world-class quality management systems and consistently delivering exceptional precision in our rubber manufacturing.

How do I get started with a project?

Simply contact our team with your project details. We'll schedule a consultation, discuss your requirements, and provide a comprehensive quote and project timeline.

The Latest

View all-

What Are Urethane Sheets? Complete Guide to Pol...

What Are Urethane Sheets? Complete Guide to Polyurethane Material Urethane sheets are appearing in more industrial applications every year, but many professionals still wonder: what exactly are they, and why...

What Are Urethane Sheets? Complete Guide to Pol...

What Are Urethane Sheets? Complete Guide to Polyurethane Material Urethane sheets are appearing in more industrial applications every year, but many professionals still wonder: what exactly are they, and why...

-

What is PTFE Sheets: The Complete Guide to Poly...

Complete guide to PTFE sheets properties, universal chemical resistance, and applications. Learn about Teflon specifications for pharmaceutical, food processing, and chemical manufacturing sealing.

What is PTFE Sheets: The Complete Guide to Poly...

Complete guide to PTFE sheets properties, universal chemical resistance, and applications. Learn about Teflon specifications for pharmaceutical, food processing, and chemical manufacturing sealing.

Transform Your Rubber Manufacturing Challenges into Precision Rubber Solutions - Contact Us Today