THERMO-SUPER NATURAL RUBBER

-

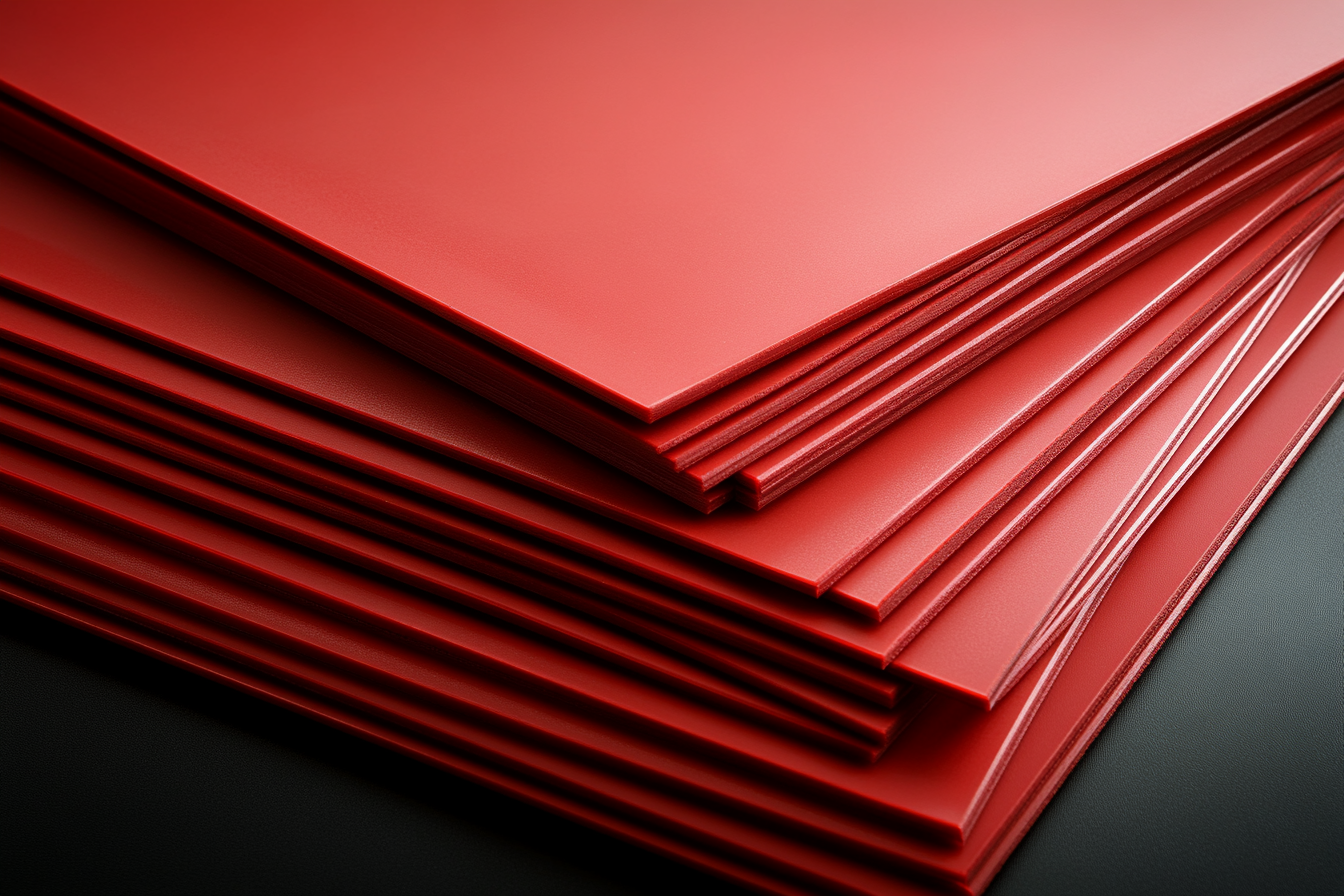

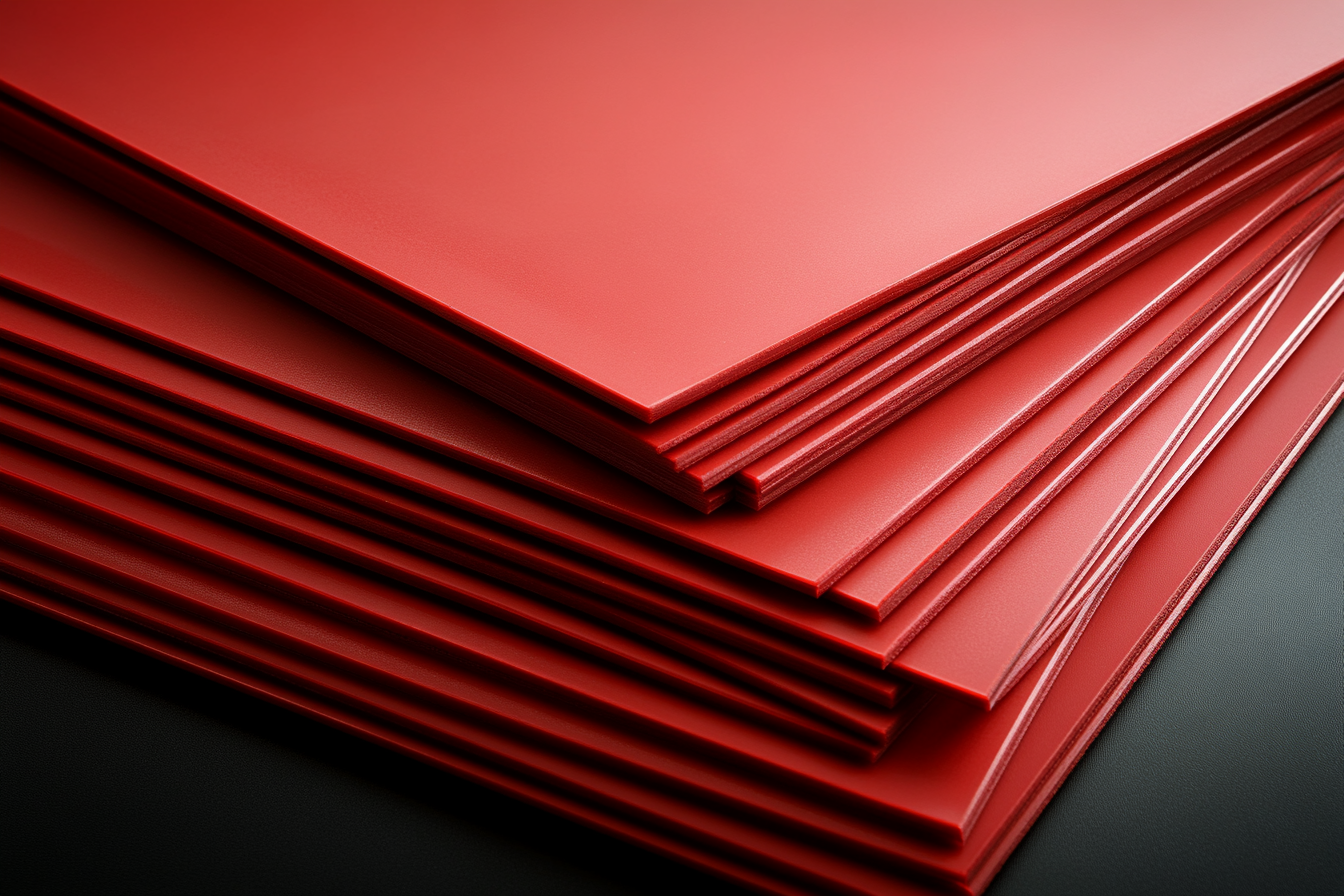

1/8" Thick - 40A Durometer - Both Sides Smooth - Red - Thermo-Super

Regular price From $137.00 USDRegular priceUnit price / per -

1/4" Thick - 40A Durometer - Both Sides Smooth - Red - Thermo-Super

Regular price From $339.00 USDRegular priceUnit price / per -

3/8" Thick - 40A Durometer - Both Sides Smooth - Red - Thermo-Super

Regular price From $506.00 USDRegular priceUnit price / per -

1/2" Thick - 40A Durometer - Both Sides Smooth - Red - Thermo-Super

Regular price From $675.00 USDRegular priceUnit price / per -

1/8" Thick - 40A Durometer - CN Bonding Layer - Red - Thermo-Super

Regular price From $194.00 USDRegular priceUnit price / per -

1/4" Thick - 40A Durometer - CN Bonding Layer - Red - Thermo-Super

Regular price From $343.00 USDRegular priceUnit price / per -

3/8" Thick - 40A Durometer - CN Bonding Layer - Red - Thermo-Super

Regular price From $491.00 USDRegular priceUnit price / per -

1/2" Thick - 40A Durometer - CN Bonding Layer - Red - Thermo-Super

Regular price From $797.00 USDRegular priceUnit price / per -

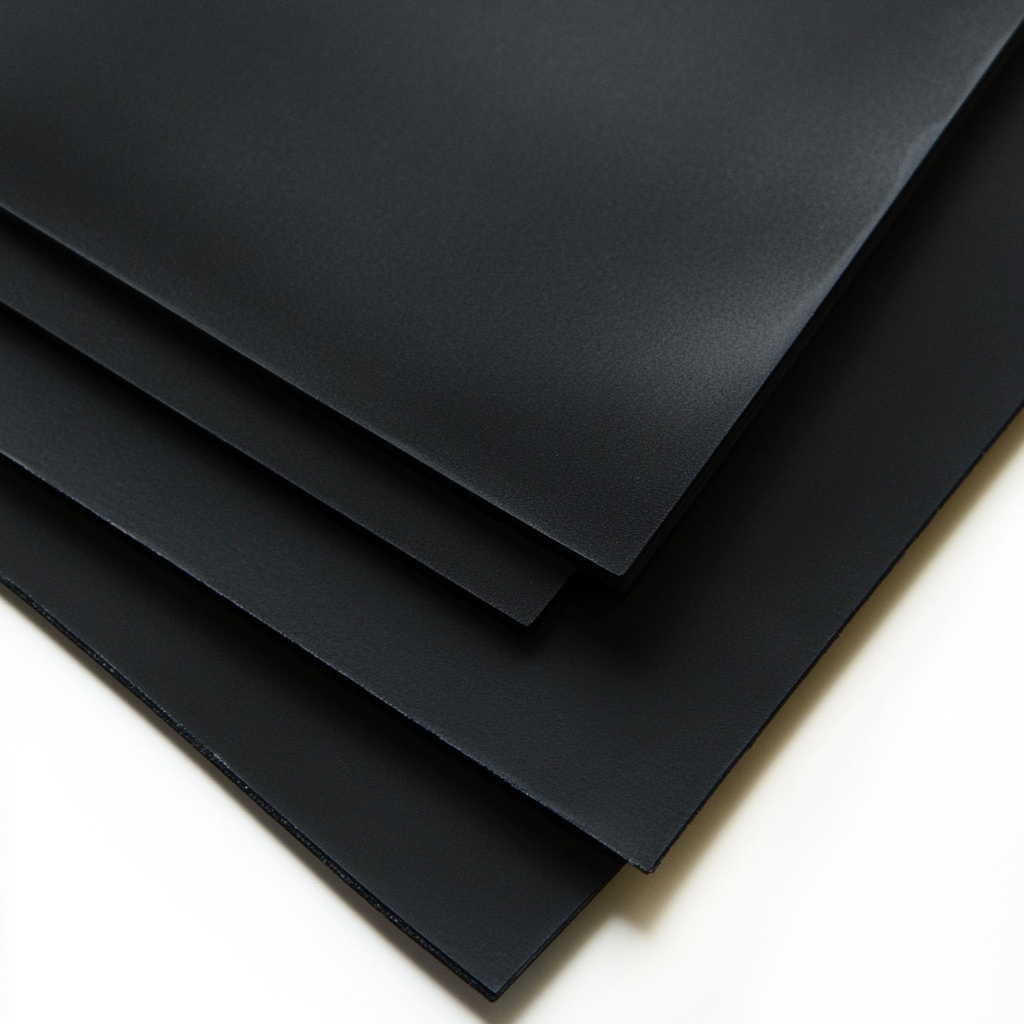

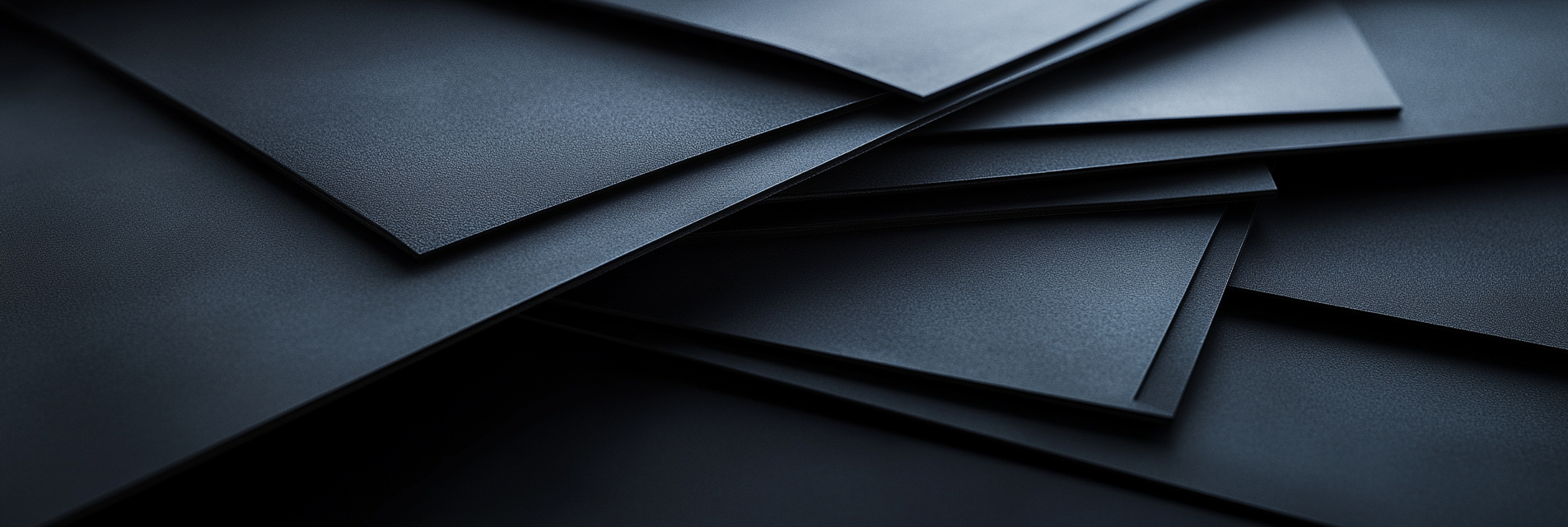

1/2" Thick - 60A Durometer - Both Sides Smooth - Black - Thermo-Super

Regular price From $588.00 USDRegular priceUnit price / per -

1/4" Thick - 60A Durometer - CN Bonding Layer - Black - Thermo-Super

Regular price From $571.00 USDRegular priceUnit price / per -

3/8" Thick - 60A Durometer - CN Bonding Layer - Black - Thermo-Super

Regular price From $813.00 USDRegular priceUnit price / per -

1/2" Thick - 60A Durometer - CN Bonding Layer - Black - Thermo-Super

Regular price From $787.00 USDRegular priceUnit price / per

Table of Contents: Thermo-Super Natrual Rubber

- Thermo-Super Natural Rubber: Premium Abrasion-Resistant Material for Heavy Industry

- Superior Properties of Thermo-Super That Outperform Linatex and Durashield

- Thermo-Super Types: Smooth Finish and CN Bonding Layer Configurations

- Thermo-Super Sheet Sizes, Durometers, and Customization Options

- Industrial Applications for Thermo-Super Natural Rubber in Mining and Aggregate

- How to Install Thermo-Super Sheets: Adhesives and Application Methods

- Thermo-Super Lifespan: Why Premium Natural Rubber Provides Maximum Value

- Frequently Asked Questions About Thermo-Super Natural Rubber Sheets and Applications

Thermo-Super Natural Rubber: Premium Abrasion-Resistant Material for Heavy Industry

Thermo-Super represents the pinnacle of natural rubber technology, engineered as a cost-effective alternative to premium brands like Linatex® and Durashield®. This advanced natural rubber compound delivers exceptional abrasion and tear resistance, making it the optimal choice for mining, cement, aggregate, and glass manufacturing applications where standard rubber materials quickly fail. Known for its outstanding performance in both wet slurry and dry material handling, Thermo-Super natural rubber maintains superior flexibility while providing maximum durability in the harshest industrial environments. Whether you need Thermo-Super rubber sheets for chute linings, conveyor protection, or equipment wear plates, this remarkable material provides reliable service in conditions that would rapidly degrade conventional elastomers.

Browse Additional Gasket Material Options

-

Viton® Rubber

Viton® Rubber Viton® Rubber Sheets Viton® Fluoroelastomer Premium Viton® rubber sheets now...

-

PTFE Sheets

PTFE Sheets Our premium PTFE sheets (also known as Teflon sheets) are...

-

Nitrile Rubber

Nitrile Rubber Our nitrile rubber is formulated for exceptional oil and chemical...

Superior Properties of Thermo-Super Natural Rubber

Thermo-Super natural rubber offers an exceptional combination of properties that make it ideal for demanding abrasion environments:

- Superior Abrasion Resistance: Exceptional wear performance that rivals premium brands at competitive pricing

- Outstanding Slurry Handling: Pure natural rubber excels in wet material applications and slurry processing

- High Tensile Strength: 3,625 PSI tensile strength for maximum durability under stress

- Excellent Elongation: 900% elongation provides superior impact absorption and flexibility

- Cut and Tear Resistance: Inherent properties of natural rubber provide excellent resistance to mechanical damage

- Noise Reduction: Advanced compound minimizes operational noise and equipment vibration

- Compression Recovery: Maintains shape and sealing properties under repeated compression cycles

These properties make Thermo-Super natural rubber sheets the preferred choice for applications requiring maximum abrasion resistance combined with cost-effective performance in mining, aggregate, and heavy industrial environments.

Comprehensive Rubber Solutions: Beyond Thermo-Super Sheets & Rolls

-

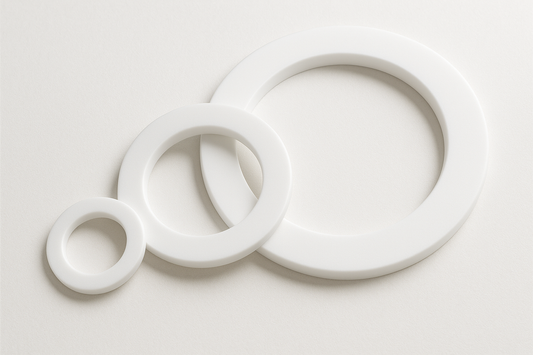

Gasket Fabrication

Our precision gasket fabrication services transform neoprene and other rubber materials into custom-fit sealing solutions for any application. Using advanced cutting technologies and quality materials, we produce gaskets to your exact specifications with quick turnaround times. From simple washers to complex die-cut shapes, our fabrication capabilities ensure optimal performance and leak-free sealing for your most demanding projects.

-

Rubber Molding

Our rubber molding expertise allows us to create custom neoprene components with exceptional consistency and precision. We utilize compression, transfer, and injection molding techniques to produce complex shapes that maintain tight tolerances and superior performance characteristics. Whether you need small production runs or high-volume manufacturing, our molding capabilities deliver durable rubber parts that perfectly match your engineering requirements.

-

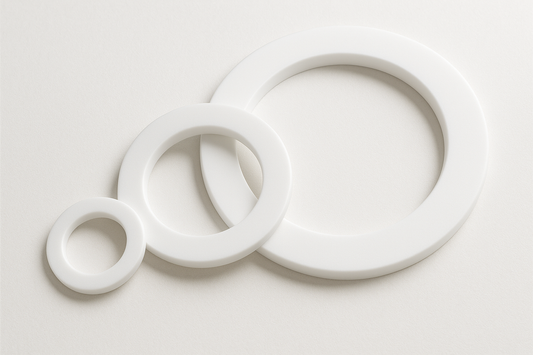

Lathe Cut Ring Gaskets

Our specialized lathe cutting technology produces precise neoprene ring gaskets with exceptional dimensional accuracy and clean edges. These precision-machined seals offer superior performance for critical applications in fluid handling, pressure vessels, and mechanical systems. Available in various cross-sections and diameters, our lathe cut rings provide reliable sealing solutions without the tooling costs associated with molded products.

Thermo-Super Types: Smooth Finish and CN Bonding Layer Configurations

Thermo-Super natural rubber is available in two distinct surface configurations, each engineered for specific installation requirements:

- Smooth Finish Both Sides: Smooth finish Thermo-Super features a uniform, non-textured surface on both sides, providing maximum flexibility for installation methods. This configuration offers excellent abrasion resistance while allowing for various adhesive options or mechanical fastening systems. Smooth finish Thermo-Super is ideal for applications where installation flexibility is important, such as removable wear plates, temporary equipment protection, and applications requiring custom adhesive selection.

- CN Bonding Layer Configuration: Thermo-Super with CN bonding layer features a specialized adhesive backing that ensures permanent, long-lasting installation. The CN bonding system maintains bond integrity even under extreme conditions, vibration, and temperature fluctuations. This professional-grade adhesive backing eliminates the need for separate contact adhesives and provides superior holding power compared to traditional installation methods. CN bonding layer Thermo-Super is perfect for permanent installations in chute linings, conveyor systems, and critical equipment protection where bond failure is not acceptable.

Durometer Options for Specific Applications

Thermo-Super is available in two primary durometer ranges to match application requirements:

- 40 Shore A durometer for maximum flexibility and impact absorption

- 60 Shore A durometer for applications requiring firmer material with enhanced cut resistance

Choosing between smooth finish and CN bonding layer depends on your installation requirements, with CN bonding providing the most reliable permanent installation for critical applications.

Modern Rubber Products

1/2" Thick - 40A Durometer - Both Sides Smooth - Red - Thermo-Super

Share

Thermo-Super Sheet Sizes, Durometers, and Customization Options

Thermo-Super natural rubber sheets are available in various thicknesses and dimensions to meet diverse heavy-industry application requirements:

Thermo-Super Sheet Thicknesses: Thermo-Super natural rubber sheets are available in a comprehensive range of thicknesses to suit virtually any abrasion-resistant application:

- 1/8" - Standard thickness for general chute linings and moderate abrasion applications

- 3/16" - Enhanced durability for high-impact environments and heavy material flow

- 1/4" - Heavy-duty applications requiring maximum abrasion resistance and impact protection

- 3/8" - Superior performance for extreme abrasion conditions and large equipment protection

- 1/2" - Maximum thickness offering ultimate durability for the most demanding mining applications

Available Widths and Custom Cutting Thermo-Super sheets come in multiple width options to minimize waste and reduce installation costs:

- 48" width for standard equipment and moderate coverage areas

- 60" width for larger equipment protection and reduced seam requirements

- 78" width for maximum coverage applications where seamless protection is critical

All widths are available in custom cut lengths of 3, 6, 9, 12, 15, 24, and 33 linear feet to match specific project requirements.

Durometer and Color Options

- 40 Shore A Durometer: Maximum flexibility for impact absorption and irregular surfaces (Available in Red or Black)

- 60 Shore A Durometer: Firmer material for enhanced cut resistance and structural applications (Available in Red or Black)

Surface Configuration Choices

- Smooth finish both sides for installation flexibility

- CN bonding layer on one side for permanent adhesion applications

The cost of Thermo-Super natural rubber sheets varies based on thickness, durometer, and surface configuration, with CN bonding layer and thicker sheets commanding a premium that is offset by their exceptional performance and reduced installation costs.

Industrial Applications for Thermo-Super Natural Rubber in Mining and Aggregate

Thermo-Super natural rubber excels across numerous heavy industries due to its exceptional abrasion resistance and slurry handling capabilities:

Mining Operations

- Chute Linings: Thermo-Super provides superior wear protection in ore and coal transfer chutes

- Conveyor Skirting: Outstanding sealing and abrasion resistance for belt conveyor systems

- Cyclone Linings: Excellent performance in mineral separation equipment exposed to abrasive slurries

- Storage Bin Protection: Thermo-Super sheets protect hoppers and bins from material impact and abrasion

Cement and Aggregate Processing

- Transfer Chute Protection: Superior abrasion resistance for sand, gravel, and aggregate handling systems

- Screening Equipment: Thermo-Super provides noise reduction and wear protection for sizing equipment

- Pipe Linings: Excellent slurry handling capabilities for material transport systems

- Impact Plates: Maximum protection for equipment exposed to falling materials and high-impact conditions

Glass Manufacturing

- Batch House Equipment: Thermo-Super resists abrasion from glass batch materials and cullet

- Conveyor Protection: Excellent performance in glass handling and transport systems

- Noise Dampening: Advanced compound reduces operational noise in glass production facilities

Heavy Industrial Applications

- Wear Plates: Thermo-Super sheets provide equipment protection in steel mills and foundries

- Launder Linings: Superior performance in material transfer systems and launders

- Flat Cell Protection: Excellent abrasion resistance for thickening and settling equipment

- Vibration Isolation: Natural rubber properties provide excellent vibration dampening

From specialized high-abrasion formulations to standard industrial grades, Thermo-Super's versatility makes it essential across numerous industries requiring reliable performance in extreme abrasion environments where premium materials like Linatex and Durashield have traditionally been required.

How to Install Thermo-Super Sheets: Adhesives and Application Methods

Proper installation of Thermo-Super natural rubber sheets ensures optimal performance and maximum lifespan:

Recommended Adhesives for Thermo-Super Natural Rubber

For permanent bonding of smooth finish Thermo-Super sheets, several adhesive types provide excellent results:

- Contact Adhesives: Solvent-based contact adhesives create immediate bond strength and are ideal for large sheet applications

- Structural Epoxies: Two-part epoxies provide excellent chemical resistance and bond strength for critical applications

- Polyurethane Adhesives: Flexible polyurethane adhesives accommodate thermal expansion while maintaining strong bonds

CN Bonding Layer Installation

Thermo-Super with CN bonding layer simplifies installation with professional results:

- Surface Preparation: Clean all surfaces thoroughly to remove dust, oils, and loose materials

- Temperature Considerations: Install at temperatures between 50°F and 100°F for optimal bonding

- Pressure Application: Apply consistent pressure across the entire surface using pneumatic rollers

- Immediate Bond: CN bonding provides immediate holding power with no curing time required

Installation Process for Smooth Finish Thermo-Super

- Surface Preparation: Ensure substrate is clean, dry, and free from oils or contaminants

- Template Creation: Create precise templates for complex shapes or equipment configurations

- Cutting: Cut Thermo-Super sheets with sharp utility knives, allowing slight excess for final trimming

- Adhesive Application: Apply chosen adhesive according to manufacturer's specifications

- Positioning: Carefully position sheets to avoid air bubbles and ensure complete contact

- Pressure and Curing: Apply even pressure and allow appropriate curing time before service

Mechanical Fastening Options For temporary installations or extreme conditions:

- Use stainless steel fasteners to prevent corrosion

- Pre-drill holes slightly smaller than fastener diameter

- Use large washers to distribute stress across the Thermo-Super material

- Apply appropriate sealants around fastener penetrations

Quality Assurance Tips

- Verify complete adhesion by checking for hollow spots or air bubbles

- Test small sections before proceeding with large installations

- Maintain installation records for warranty and maintenance purposes

Proper installation techniques are critical to maximize the abrasion resistance and durability characteristics that make Thermo-Super the cost-effective alternative to premium natural rubber brands.

The Rubber Blog: Tips, Trends & Technical Insights

View all-

What Are Urethane Sheets? Complete Guide to Pol...

What Are Urethane Sheets? Complete Guide to Polyurethane Material Urethane sheets are appearing in more industrial applications every year, but many professionals still wonder: what exactly are they, and why...

What Are Urethane Sheets? Complete Guide to Pol...

What Are Urethane Sheets? Complete Guide to Polyurethane Material Urethane sheets are appearing in more industrial applications every year, but many professionals still wonder: what exactly are they, and why...

-

What is PTFE Sheets: The Complete Guide to Poly...

Complete guide to PTFE sheets properties, universal chemical resistance, and applications. Learn about Teflon specifications for pharmaceutical, food processing, and chemical manufacturing sealing.

What is PTFE Sheets: The Complete Guide to Poly...

Complete guide to PTFE sheets properties, universal chemical resistance, and applications. Learn about Teflon specifications for pharmaceutical, food processing, and chemical manufacturing sealing.

-

What is Viton Rubber: The Complete Guide to Flu...

Complete guide to Viton rubber properties, chemical resistance, and high-temperature applications. Learn about fluoroelastomer specifications for chemical processing, aerospace, and extreme environment sealing.

What is Viton Rubber: The Complete Guide to Flu...

Complete guide to Viton rubber properties, chemical resistance, and high-temperature applications. Learn about fluoroelastomer specifications for chemical processing, aerospace, and extreme environment sealing.

Thermo-Super Lifespan: Why Premium Natural Rubber Provides Maximum Value

The exceptional durability of Thermo-Super natural rubber makes it a cost-effective alternative to premium brands while delivering comparable performance:

Expected Lifespan of Thermo-Super Natural Rubber

When properly installed and maintained, Thermo-Super products typically last:

- 3-7 years for chute linings in extreme abrasion mining applications

- 5-10 years for conveyor skirting and equipment protection in aggregate processing

- 7-15 years for moderate abrasion applications and noise dampening installations

This impressive longevity stems from the advanced formulation of premium natural rubber compounds that rival expensive alternatives like Linatex and Durashield.

Factors Affecting Thermo-Super Longevity

Several factors influence how long Thermo-Super sheets will maintain their performance:

- Material Characteristics: Sharp, angular materials cause more rapid wear than rounded aggregates

- Impact Velocity: Higher impact speeds and drop heights increase wear rates

- Chemical Exposure: Strong acids, oils, and solvents can affect natural rubber properties

- Temperature Extremes: Continuous operation near temperature limits may reduce service life

- Installation Quality: Proper installation with appropriate adhesives significantly extends lifespan

Maintaining Thermo-Super Products To maximize the lifespan of Thermo-Super installations:

- Regularly inspect for signs of edge lifting, cuts, or excessive wear

- Remove sharp debris that could cause premature cutting or tearing

- Monitor installation temperatures and adjust material selection if needed

- Replace sections showing significant wear before complete failure occurs

- Clean installations with water and mild detergent, avoiding petroleum-based solvents

Cost-Effectiveness Compared to Premium Brands

- Thermo-Super provides exceptional value when compared to premium alternatives:

- Lower initial material cost while delivering comparable wear performance

- Reduced installation costs due to available width options and custom cutting

- Extended equipment life and reduced maintenance costs justify premium over standard rubber

- Competitive performance against Linatex and Durashield at significantly lower cost

The superior abrasion resistance and cost-effectiveness of Thermo-Super natural rubber provide outstanding value over time, particularly in applications where premium performance is required but budget constraints make traditional premium brands cost-prohibitive.

Frequently Asked Questions About Thermo-Super Natural Rubber Sheets and Applications

How does Thermo-Super compare to Linatex and Durashield?

Super is engineered to provide comparable abrasion resistance and performance to these premium brands while offering significant cost savings. Independent testing shows similar wear rates in most applications, with Thermo-Super offering the additional benefits of multiple durometer options and flexible installation configurations. For most mining and aggregate applications, Thermo-Super provides equivalent performance at a fraction of the cost.

What is the difference between 40A and 60A durometer Thermo-Super?

40A durometer Thermo-Super offers maximum flexibility and impact absorption, making it ideal for applications with irregular surfaces or high-impact conditions. 60A durometer provides firmer material with enhanced cut resistance, better suited for applications where sharp materials or high abrasion rates are encountered. Both offer excellent abrasion resistance, with durometer selection based on specific application requirements.

Can Thermo-Super be used in wet slurry applications?

Yes, Thermo-Super excels in slurry handling applications. Natural rubber's inherent properties make it particularly outstanding when handling wet materials and slurries. The material maintains its flexibility and abrasion resistance in wet conditions, making it ideal for cyclones, launders, and other equipment processing wet materials.

What installation method provides the longest service life?

CN bonding layer installation typically provides the longest service life by ensuring consistent, permanent adhesion that prevents edge lifting and premature failure. However, proper installation of smooth finish Thermo-Super with appropriate contact adhesives can achieve similar results. The key is complete surface preparation and consistent pressure during installation.

How should Thermo-Super be stored before installation?

Store Thermo-Super sheets in a cool, dry location away from direct sunlight and heat sources. Avoid contact with oils, solvents, and sharp objects. Store sheets flat or in loose rolls to prevent permanent creasing. Proper storage maintains material properties and ensures optimal installation results.

Understanding these aspects of Thermo-Super natural rubber helps ensure you select the right configuration and installation method for your specific application requirements, particularly in demanding abrasion environments where cost-effective performance is essential.