PTFE (TEFLON) SHEETS

-

1/64" Thick - Virgin Grade PTFE (Teflon) Sheets

Regular price From $7.81 USDRegular priceUnit price / per -

1/32" Thick - Virgin Grade PTFE (Teflon) Sheets

Regular price From $15.63 USDRegular priceUnit price / per -

1/16" Thick - Virgin Grade PTFE (Teflon) Sheets

Regular price From $29.30 USDRegular priceUnit price / per -

3/32" Thick - Virgin Grade PTFE (Teflon) Sheets

Regular price From $44.21 USDRegular priceUnit price / per -

1/8" Thick - Virgin Grade PTFE (Teflon) Sheets

Regular price From $53.05 USDRegular priceUnit price / per -

3/16" Thick - Virgin Grade PTFE (Teflon) Sheets

Regular price From $88.41 USDRegular priceUnit price / per -

1/4" Thick - Virgin Grade PTFE (Teflon) Sheets

Regular price From $106.10 USDRegular priceUnit price / per

PTFE FAQs

What is the difference between PTFE and Teflon sheets?

PTFE (Polytetrafluoroethylene) is the chemical name for the material, while Teflon is DuPont's brand name for their PTFE products. All Teflon sheets are PTFE, but not all PTFE sheets are made by DuPont. Our virgin PTFE sheets offer the same exceptional properties regardless of brand name.

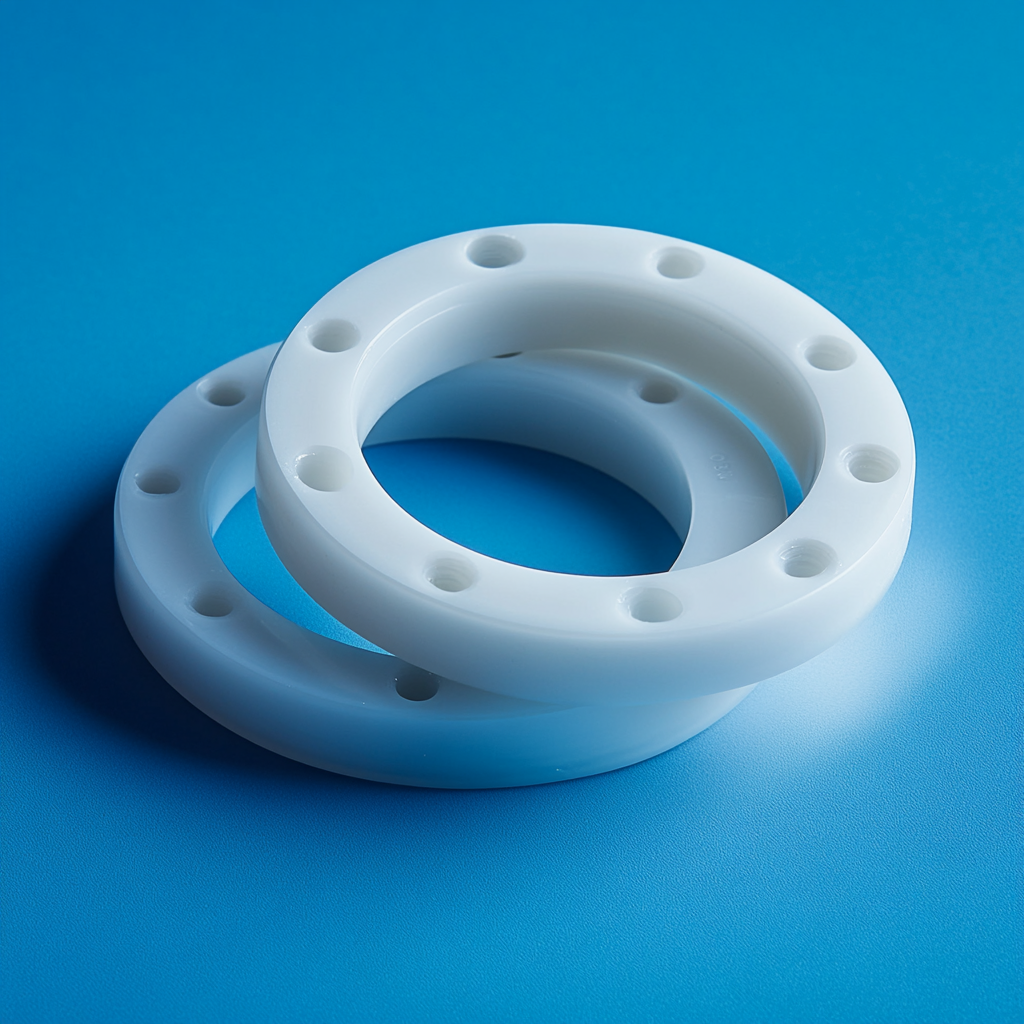

What are the main applications for PTFE sheets?

PTFE sheets are widely used for gaskets, seals, bearings, slide plates, electrical insulation, chemical barriers, and food processing equipment. The material's low friction, chemical resistance, and wide temperature tolerance make virgin PTFE sheets suitable for numerous industrial applications.

How do I know which thickness of PTFE sheet to choose?

The required thickness depends on your application. Thinner sheets (1/64" to 1/16") are ideal for gaskets and electrical insulation, while thicker PTFE sheets (1/8" to 1/4") provide better structural support for mechanical applications. Contact our team for personalized recommendations.

Can PTFE sheets be cut or machined to custom dimensions?

Yes, our virgin PTFE sheets can be easily cut, drilled, and machined using standard tools. The material maintains its properties even after fabrication, making it ideal for custom components. Reach out to us for a quote on any fabricated PTFE needs.

Are your PTFE sheets FDA compliant?

Yes, our virgin PTFE sheets comply with FDA regulations for food contact, making them suitable for food processing equipment and pharmaceutical applications where purity is essential.

How should PTFE sheets be stored?

PTFE sheets should be stored flat in a clean, dry environment to prevent warping or deformation. Avoid stacking heavy items on top of the sheets, especially for thinner gauges. Keep them away from direct sunlight and extreme temperature fluctuations. For optimal preservation, store sheets between flat, rigid boards to maintain their flatness, and handle with clean gloves to prevent contamination of the surface.

What is the temperature range of PTFE sheets?

Our virgin PTFE sheets maintain their excellent properties across an impressive temperature range from -100°F to 500°F (-73°C to 260°C). This wide operating range makes PTFE sheets suitable for both cryogenic applications and high-temperature environments, offering reliable performance without degradation throughout this temperature spectrum.

Chemical Resistance of Virgin PTFE Sheets

PTFE sheets offer exceptional chemical resistance, making them ideal for applications involving aggressive substances:

- Universal Chemical Resistance: Our virgin PTFE sheets resist nearly all industrial chemicals, acids, bases, solvents, and fuels.

- Inert Material: PTFE is chemically inert, preventing reactions with process fluids or gases.

- pH Range Tolerance: Effective across the entire pH scale (0-14).

- Zero Water Absorption: Our Teflon sheets won't absorb moisture or swell when exposed to liquids.

- Aging Resistance: PTFE maintains its chemical properties over extended periods, even when continuously exposed to harsh chemicals.

- No Leaching: Virgin PTFE won't contaminate sensitive materials or chemicals it contacts.

This exceptional chemical resistance makes our PTFE sheets ideal for chemical processing equipment, laboratory fixtures, and pharmaceutical manufacturing components.

Physical Characteristics

Our virgin PTFE (Teflon) sheets provide an outstanding combination of physical properties:

- Temperature Range: Maintains performance from -100°F to 500°F (-73°C to 260°C)

- Coefficient of Friction: One of the lowest of any solid material (0.05-0.10)

- Density: Approximately 2.2 g/cm³

- Tensile Strength: 3,000-4,000 psi

- Dielectric Strength: Excellent electrical insulator (500-600 V/mil)

- Thermal Conductivity: Low (0.25 W/m-K)

- Hardness: Shore D 50-65

- UV Resistance: Excellent outdoor weatherability

- Color: Natural white/off-white

- Flammability: Self-extinguishing, UL 94 V-0 compliant

The unique combination of low friction, high temperature resistance, and excellent electrical properties makes virgin PTFE sheets suitable for applications where other plastics would fail.

Installation & Handling Guidelines

Cutting & Fabrication:

- Use sharp, clean cutting tools to prevent material deformation

- Support PTFE sheets fully during cutting to ensure clean edges

- Standard woodworking and metalworking tools work well with Teflon sheets

- Maintain slower cutting speeds than those used for metals

Installation Tips:

- Allow adequate expansion space when installing PTFE sheets in confined areas

- Use appropriate fasteners that won't deform the material

- Avoid overtightening bolts when using PTFE as gasket material

- Clean surfaces thoroughly before installation to maintain non-stick properties

Handling Precautions:

- Store virgin PTFE sheets flat to prevent warping

- Keep sheets clean and free from oils or contaminants

- Wear clean gloves when handling to prevent fingerprints

- Avoid folding or creasing thin PTFE sheets

Temperature Considerations:

- Account for thermal expansion in applications with temperature fluctuations

- Pre-condition PTFE sheets at application temperature for critical dimensional requirements

-

Cost Benefit Analysis

Value Proposition of Virgin PTFE Sheets

- Extended service life reduces long-term replacement costs

- Minimal maintenance requirements lower operational expenses

- No need for additional lubricants or release agents

- Elimination of downtime due to material failure

- Prevention of product contamination in processing applications

- Simplified cleaning procedures due to non-stick properties

-

Maintenance & Care

Maintaining PTFE Sheet Performance

- Clean with mild soap and water; avoid abrasive cleaning methods

- Periodically inspect for surface damage, wear, and fastener compression

- Store unused sheets flat in a clean, dry environment

- Keep away from sharp objects, excessive dust, and dirt

- Avoid stacking heavy items on PTFE sheets

- Protect from direct sunlight and extreme temperature fluctuations

-

Manufacturing Process

How Our Virgin PTFE Sheets Are Produced

- Only premium virgin PTFE resin with verified purity is used

- Compression molding or skived followed by controlled sintering ensures material integrity

- Precision skiving process creates thinner sheets with consistent thickness

- Rigorous quality control includes dimensional verification and surface inspection

- Edge trimming and finishing meets exact specifications

- Final inspection ensures superior quality in every sheet

-

Material Grade Selection Guide

Choosing the Right PTFE Sheet for Your Application

- Standard Virgin PTFE: Ideal for gaskets, seals, and electrical insulation

- Glass-Filled PTFE: Best for higher load applications with improved wear resistance

- Carbon-Filled PTFE: Suitable for electrical applications requiring static dissipation

- Bronze-Filled PTFE: Excellent for bearing and high-wear applications

- Special grades available for extreme chemical environments

Contact our technical team for application-specific recommendations

-

Custom Solutions & Capabilities

- Custom thickness options

- Special durometer formulations

- Custom width cutting

- Specific surface finish requirements

- Special packaging options

- Rush order processing

-

Related Services

We also offer the following services:

- Rubber Injection Molding

- Gasket fabrication

- Water jet cutting

- Die cutting

- Slitting services

- Custom cutting to size

Reach out for any inquires on the listed services above.