custom rubber parts

Manufacturing Capabilities

With decades of rubber manufacturing experience, Modern Rubber Products, has positioned itself as a leader in custom component solutions. With extensive experience across multiple industries, we've developed comprehensive manufacturing expertise that allows us to tackle virtually any rubber engineering challenge. We've seen it all and engineered it all – so if you're facing a complex rubber manufacturing problem, chances are we've not only encountered it before, but we've already developed a superior solution.

-

Molded Rubber Products

Learn More -

Die-Cut Parts

Learn More -

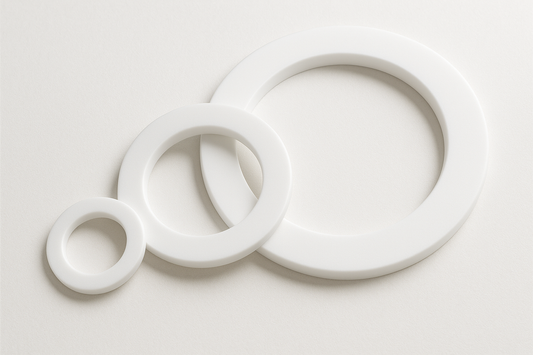

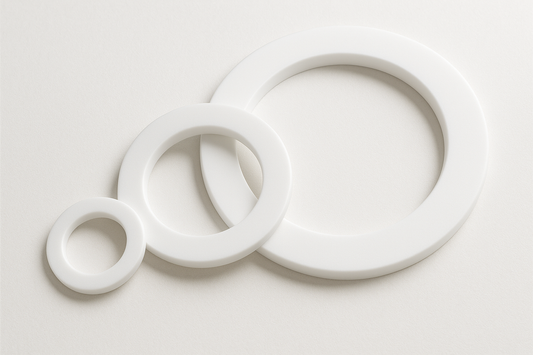

Lathe-Cut Gaskets

Learn More -

Vulcanization & Cold Bonded Parts

Learn More -

Waterjet-Cut Parts

Learn More -

Cut-To-Length Materials

Shop Now

Latest

View all-

What is PTFE Sheets: The Complete Guide to Poly...

Complete guide to PTFE sheets properties, universal chemical resistance, and applications. Learn about Teflon specifications for pharmaceutical, food processing, and chemical manufacturing sealing.

What is PTFE Sheets: The Complete Guide to Poly...

Complete guide to PTFE sheets properties, universal chemical resistance, and applications. Learn about Teflon specifications for pharmaceutical, food processing, and chemical manufacturing sealing.

-

What is Viton Rubber: The Complete Guide to Flu...

Complete guide to Viton rubber properties, chemical resistance, and high-temperature applications. Learn about fluoroelastomer specifications for chemical processing, aerospace, and extreme environment sealing.

What is Viton Rubber: The Complete Guide to Flu...

Complete guide to Viton rubber properties, chemical resistance, and high-temperature applications. Learn about fluoroelastomer specifications for chemical processing, aerospace, and extreme environment sealing.