What Are Urethane Sheets? Complete Guide to Polyurethane Material

Share

What is a Urethane Sheet?

A urethane sheet (also called a polyurethane sheet) is a flat, durable polymer material made from polyurethane elastomer. These sheets combine the flexibility of rubber with the toughness and durability of metal, offering superior abrasion resistance, chemical resistance, and load-bearing capacity compared to traditional rubber materials.

Urethane sheets are manufactured through a casting process that creates consistent, high-quality material with precise tolerances. The sheets are available in various thicknesses (typically 1/8" to 5/8"), hardnesses (measured in Shore A durometer from 40A to 90A), and sizes ranging from small 12"x12" sheets to large 48"x48" industrial formats.

The terms "urethane" and "polyurethane" are used interchangeably in the industry. They refer to the same material. Polyurethane is the technical chemical name, while urethane is the common industry shorthand that most professionals use.

Why Are Urethane Sheets Important?

Urethane sheets have become essential in modern industrial applications for several compelling reasons that directly impact your bottom line and operational efficiency.

Superior Durability and Longevity

Urethane sheets last 5-10 times longer than traditional rubber in high-wear applications. This extended lifespan translates to reduced replacement costs, less downtime for maintenance, and improved productivity. In abrasion-intensive environments like material handling and metal forming, polyurethane's exceptional resistance to wear means fewer replacements and lower total cost of ownership.

Exceptional Chemical and Oil Resistance

Unlike rubber, which degrades when exposed to oils and many industrial chemicals, urethane maintains its properties in harsh environments. Polyurethane sheets resist mineral-based oils, greases, hydrocarbons, and many solvents that would destroy rubber components. This makes them ideal for automotive, manufacturing, and food processing applications where chemical exposure is routine.

Wide Range of Hardness Options

One of urethane's most valuable properties is its availability in a broad hardness range. From very soft 40A durometer (perfect for cushioning) to hard 90A durometer (ideal for wear resistance), you can select the exact hardness needed for your application. This versatility means one material type can replace multiple rubber compounds in your facility.

Superior Load-Bearing Capacity

Urethane sheets maintain their shape under repeated loading thanks to excellent compression set resistance and elastic memory. In press brake applications, die cutting, and stamping operations, polyurethane outperforms rubber by maintaining consistent performance over thousands of cycles. This reliability ensures consistent part quality and reduces reject rates.

According to industry studies, facilities that switch from rubber to urethane for high-wear components report maintenance cost reductions of 40-60% and see equipment uptime improvements of 15-25%.

Real Examples of Urethane Sheets in Action

Understanding how urethane sheets perform in real-world applications helps illustrate their versatility and value.

Die Cutting and Stamping Operations

Manufacturing facilities use urethane sheets as cutting pads and press brake dies because the material's durability withstands repeated high-pressure impacts. A typical rubber cutting pad might last 500-1,000 cycles, while a urethane pad in the same application regularly exceeds 5,000 cycles. Our 1/4" thick urethane sheets are particularly popular for die cutting applications due to their optimal balance of cushioning and durability.

Automotive Gaskets and Seals

Automotive manufacturers and repair shops rely on urethane sheets for custom gaskets that must resist oil, heat, and constant vibration. The material's chemical resistance prevents degradation from engine oils and fluids, while its flexibility ensures proper sealing. Many automotive professionals keep 12"x12" urethane sheets in stock for creating custom gaskets on demand.

Industrial Vibration Dampening

Equipment manufacturers use urethane sheets to isolate vibration in machinery, HVAC systems, and precision instruments. The material's ability to absorb shock while maintaining its structure makes it superior to rubber for long-term vibration control. Different applications require different hardnesses. Softer durometers like 40A-60A excel at dampening, while harder durometers provide structural support.

Material Handling and Conveyor Systems

Warehouses and distribution centers use urethane sheets as chute liners, wear strips, and impact bumpers. The material's abrasion resistance means these components last years instead of months, reducing maintenance interruptions. Polyurethane's resistance to tearing also prevents catastrophic failures that can halt operations.

Metal Forming and Fabrication

Sheet metal fabricators use urethane pads in press brakes and forming operations because the material distributes pressure evenly and won't damage finished metal surfaces. The non-marking surface of polyurethane protects expensive finished parts while the material's durability ensures consistent forming results across production runs.

Browse our complete selection of urethane sheets to find the right size and hardness for your application.

Tips for Getting Started with Urethane Sheets

If you're considering switching from rubber to urethane or using polyurethane sheets for the first time, these guidelines will help ensure success.

Start with Sample Sizes

Before committing to large sheets, order smaller sizes to test different hardnesses. A 12"x12" urethane sheet provides enough material to create test parts and verify the durometer works for your application. Testing multiple hardnesses side-by-side helps you select the optimal material properties for your specific needs.

Understand Durometer Selection

Choosing the right hardness is critical for performance. Softer durometers (40A-60A) provide maximum cushioning and flexibility, which are ideal for gaskets, vibration dampening, and applications requiring conformability. Medium durometers (70A-80A) offer a balance of flexibility and wear resistance for general-purpose applications. Harder durometers (90A) maximize abrasion resistance and load-bearing capacity for heavy-duty applications. Learn more about how to choose the right durometer for your specific needs.

Consider Your Operating Environment

Evaluate temperature ranges, chemical exposure, and loading conditions in your application. Urethane performs well from -40°F to 180°F and resists most industrial chemicals, but extreme conditions may require specialty formulations. If you're unsure about material compatibility, contact us for application-specific guidance.

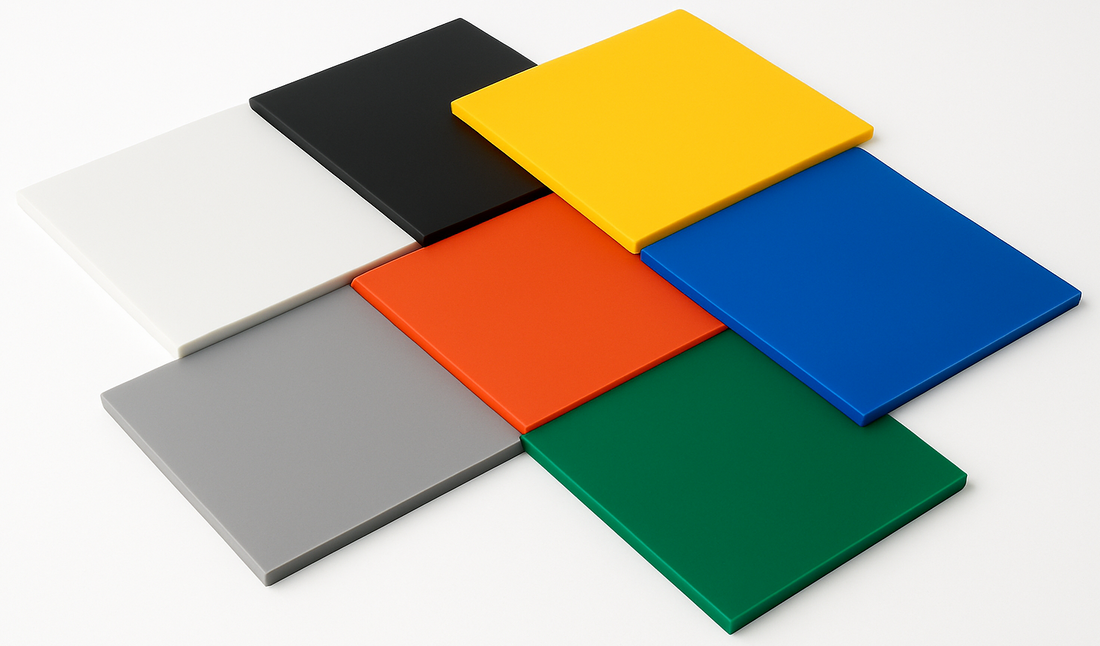

Don't Overlook Custom Options

While standard sheets cover most applications, custom manufacturing opens additional possibilities. Custom urethane sheets can be produced in specialty colors for color-coding systems, unique thicknesses for specific applications, non-standard durometers for precise performance requirements, and FDA-compliant formulations for food contact applications. Custom options typically add 7-10 business days to delivery but provide exact specifications for demanding applications.

Partner with Experienced Suppliers

Working with suppliers who understand urethane applications ensures you get the right material the first time. Look for suppliers offering multiple durometers and sizes in stock, custom waterjet cutting services for precision parts, technical support for application questions, and fast shipping to minimize downtime. We stock black and orange urethane sheets for immediate shipping and can manufacture custom specifications as needed.

Urethane sheets represent a significant advancement over traditional rubber materials, offering superior durability, chemical resistance, and versatility across countless industrial applications. By understanding what polyurethane sheets are and how they outperform rubber, you can make informed decisions that reduce costs, improve reliability, and enhance your operations.

Whether you need standard sheets for testing or production quantities for ongoing operations, starting with the right material and hardness ensures optimal performance. The investment in urethane typically pays for itself through extended service life and reduced maintenance requirements.

Ready to experience the benefits of urethane sheets in your facility? Shop our complete selection of urethane sheets available in multiple sizes, thicknesses, and durometers, with fast shipping on in-stock items.