What is PTFE Sheets: The Complete Guide to Polytetrafluoroethylene Material Properties and Applications

Share

PTFE sheets represent the pinnacle of chemical inertness and universal compatibility in industrial sealing materials, offering unmatched resistance to virtually all chemicals while maintaining excellent mechanical properties across extreme temperature ranges. This remarkable fluoropolymer material provides the ultimate solution for applications where chemical compatibility is critical and conventional elastomers cannot survive aggressive environments.

Whether you're an engineer designing sealing systems for pharmaceutical equipment, a maintenance manager sourcing gaskets for chemical processing applications, or a procurement professional evaluating materials for food-grade systems, understanding PTFE sheets' exceptional properties and versatility is essential for critical sealing applications. This comprehensive guide covers everything you need to know about PTFE sheets, from their unique characteristics to technical specifications and application considerations.

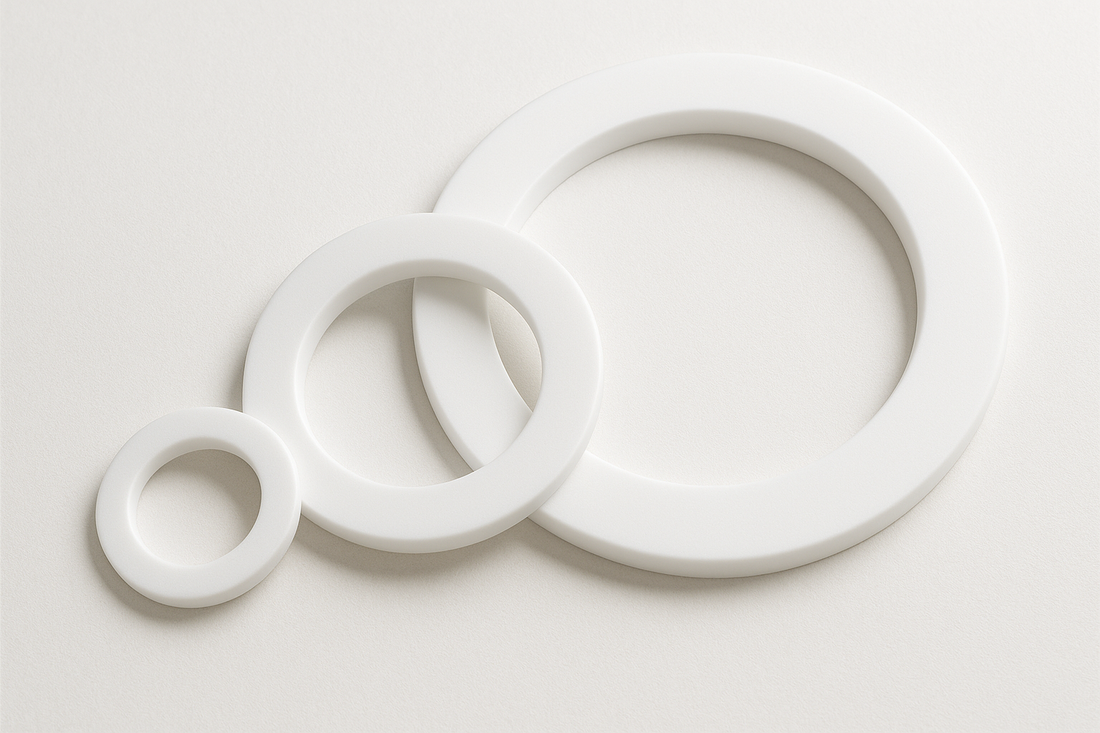

What are PTFE Sheets?

PTFE (Polytetrafluoroethylene) sheets are high-performance fluoropolymer materials composed of carbon and fluorine atoms arranged in a unique molecular structure that creates virtually universal chemical resistance. Operating effectively in temperatures ranging from -400°F to 500°F (-240°C to 260°C), PTFE sheets provide exceptional resistance to acids, bases, solvents, and virtually all industrial chemicals while maintaining excellent mechanical properties.

The fully fluorinated polymer backbone makes PTFE chemically inert to nearly all substances, with only molten alkali metals and fluorine gas at high temperatures capable of attacking the material. This exceptional chemical resistance, combined with excellent electrical properties and non-stick characteristics, makes PTFE sheets the material of choice for the most demanding chemical processing and food-grade applications.

Alternative Names for PTFE Sheets

PTFE sheets are referenced by several names and trade designations throughout various industries:

PTFE: The standard abbreviation for Polytetrafluoroethylene, universally recognized in technical specifications and engineering documentation.

Teflon: The original trade name developed by DuPont, now commonly used as a generic term for PTFE materials.

TFE: Alternative abbreviation for Tetrafluoroethylene, though PTFE is more commonly used.

Polytetrafluoroethylene: The full chemical name describing the polymer structure.

Virgin PTFE: Refers to pure PTFE without fillers or additives, offering maximum chemical resistance and purity.

Filled PTFE: PTFE modified with fillers like glass fiber, carbon, or bronze to enhance specific mechanical properties.

When specifying PTFE sheets, both "PTFE" and "Teflon" are universally understood, though PTFE is preferred in formal technical documentation and specifications.

Key Properties and Advantages of PTFE Sheets

PTFE sheets offer exceptional advantages that make them indispensable for critical chemical resistance applications:

Universal Chemical Resistance: PTFE demonstrates resistance to virtually all acids, bases, solvents, and industrial chemicals, making it suitable for the most aggressive chemical environments.

Exceptional Temperature Range: Operating reliably from -400°F to 500°F, PTFE outperforms all other sealing materials in extreme temperature applications.

Outstanding Electrical Properties: Excellent dielectric strength and low dissipation factor make PTFE ideal for electrical and electronic applications.

Non-Stick Surface: The low surface energy prevents adhesion of most substances, facilitating easy cleaning and preventing contamination.

FDA Compliance: Pure PTFE meets FDA requirements for food contact applications, making it ideal for pharmaceutical and food processing industries.

Low Friction Properties: Exceptional lubricity reduces wear and enables smooth operation in dynamic sealing applications.

Dimensional Stability: Excellent resistance to creep and deformation under load ensures long-term sealing performance.

Common Applications for PTFE Sheets

PTFE sheets' exceptional properties make them essential for demanding industrial applications:

Chemical Processing Industry: Reactor linings, pump seals, valve seats, pipe linings, and equipment gaskets for aggressive chemical environments.

Pharmaceutical Industry: Process equipment seals, reactor gaskets, transfer line seals, and components requiring ultra-high purity and FDA compliance.

Food Processing Industry: Food contact surfaces, processing equipment seals, conveyor components, and gaskets requiring FDA approval and easy cleaning.

Semiconductor Industry: Chemical delivery systems, process chamber seals, and ultra-high purity applications requiring contamination-free materials.

Electrical Industry: Insulation components, cable wrapping, electrical enclosure seals, and high-voltage applications requiring excellent dielectric properties.

Laboratory Equipment: Analytical instrument seals, laboratory glassware components, and research equipment requiring chemical inertness.

Limitations and Unsuitable Environments

While PTFE sheets provide exceptional performance, certain conditions can limit their application:

Mechanical Properties: PTFE has lower tensile strength and wear resistance compared to elastomers, requiring careful design consideration for high-stress applications.

Creep and Cold Flow: PTFE can deform under sustained load, particularly at elevated temperatures, requiring proper flange design and bolt torque management.

Thermal Cycling: Repeated temperature cycling can cause dimensional changes that may affect sealing performance in dynamic applications.

Molten Alkali Metals: Concentrated sodium, potassium, and lithium at elevated temperatures can attack PTFE, though these conditions are rarely encountered in typical applications.

Cost Considerations: PTFE sheets cost more than conventional elastomers, though the superior performance often justifies the investment.

Types of PTFE Sheets Available

PTFE sheets come in various formulations to meet specific performance requirements:

Virgin PTFE Sheets: Pure PTFE offering maximum chemical resistance and FDA compliance for pharmaceutical and food-grade applications.

Glass-Filled PTFE: Enhanced mechanical properties and reduced creep for applications requiring improved dimensional stability under load.

Carbon-Filled PTFE: Improved wear resistance and thermal conductivity for dynamic sealing applications and heat transfer requirements.

Bronze-Filled PTFE: Enhanced mechanical properties and thermal conductivity for heavy-duty industrial applications.

Expanded PTFE (ePTFE): Microporous structure providing enhanced sealing performance and conformability for irregular surfaces.

Conductive PTFE: Electrically conductive formulations for applications requiring static dissipation or electromagnetic shielding.

Temperature Range and Operating Conditions

PTFE sheets operate across an extraordinary temperature range of -400°F to 500°F (-240°C to 260°C), with optimal performance typically occurring between -200°F and 400°F. This exceptional temperature capability exceeds all other sealing materials, making PTFE suitable for cryogenic applications and high-temperature chemical processing.

For continuous service above 400°F, consider the effects of thermal cycling and potential dimensional changes. For cryogenic applications below -200°F, PTFE maintains flexibility and sealing effectiveness where other materials become brittle and fail.

Chemical Compatibility

PTFE sheets demonstrate exceptional resistance to virtually all acids including hydrofluoric acid, bases, solvents, fuels, oils, and industrial chemicals. The material resists swelling, dissolution, and chemical attack in environments that rapidly destroy other sealing materials.

Only molten alkali metals at extremely high temperatures and elemental fluorine gas can attack PTFE under normal processing conditions. This universal chemical compatibility makes PTFE the safest choice when chemical exposure is unknown or involves multiple aggressive substances.

Price Comparison with Other Sealing Materials

PTFE sheets represent a premium investment justified by exceptional performance and versatility:

PTFE vs. Viton: PTFE costs 20-40% more than Viton but provides superior chemical resistance and broader temperature range, though Viton offers better elastomeric properties.

PTFE vs. Nitrile: PTFE costs 8-12 times more than nitrile rubber but provides vastly superior chemical resistance and temperature capability for critical applications.

PTFE vs. EPDM: PTFE costs 10-15 times more than EPDM but offers universal chemical resistance and extreme temperature performance that EPDM cannot approach.

PTFE vs. Metal Gaskets: PTFE often costs less than exotic metal gaskets while providing superior chemical resistance and easier installation.

The higher cost of PTFE sheets is justified by universal chemical compatibility, extended service life, and prevention of costly contamination or failure in critical processes.

Installation and Handling Tips

When working with PTFE sheets, follow these best practices for optimal performance:

Storage: Store PTFE sheets flat in clean, dry conditions away from sharp objects that could damage the surface. PTFE's excellent aging characteristics allow indefinite storage without degradation.

Cutting and Machining: Use sharp tools and proper cutting techniques to achieve clean edges. PTFE machines easily but requires appropriate speeds and feeds to prevent material buildup.

Flange Design: Design flanges with appropriate surface finish and bolt patterns to accommodate PTFE's mechanical properties and prevent excessive creep.

Installation: Handle carefully to avoid nicks or gouges that could compromise sealing performance. Use appropriate bolt torque to compress PTFE without over-stressing the material.

Contamination Control: Maintain cleanliness during installation, as PTFE's non-stick properties make surface contamination easily removable but important to prevent.

Technical Specifications We Offer

We stock PTFE sheets in comprehensive size ranges to meet demanding chemical resistance and purity requirements:

Available Thicknesses: 1/32", 1/16", 3/32", 1/8", 3/16", 1/4", 3/8", 1/2", 5/8", 3/4", and 1" thick sheets

Sheet Widths: Available in 36" wide and 48" wide formats to accommodate large gasket applications while maintaining material integrity

Durometer Options: Standard durometers range from 40 to 70 Shore A hardness. Custom formulations available for specialized applications requiring specific mechanical properties.

Length Options: Flexible length options from 5 linear feet for specialized applications up to full 50-foot rolls for large-scale chemical processing installations

All PTFE sheets meet ASTM D1457 and FDA standards for purity and performance, suitable for precision cutting using waterjet cutting or CNC machining methods depending on thickness and geometric requirements.

PTFE sheets represent the ultimate choice for applications demanding universal chemical resistance, extreme temperature performance, and absolute purity in the most challenging industrial environments. The material's exceptional properties and FDA compliance make it indispensable for pharmaceutical, food processing, and chemical manufacturing applications.

When specifying PTFE sheets for critical applications, consider the chemical environment, temperature requirements, mechanical loads, and purity standards. Our comprehensive inventory of PTFE sheets in various thicknesses, widths, and formulations provides access to the most chemically resistant sealing materials available for your most demanding applications.

Need chemically inert PTFE sheets for critical purity and chemical resistance applications? Browse our online store to view current PTFE inventory and place orders for immediate shipment, or contact us at info@modernrubberproducts.com to discuss custom cutting services and receive a quote for precision-cut PTFE gaskets engineered for your most demanding chemical resistance and purity requirements.