NEOPRENE RUBBER

-

1/32" Thick - 40A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $26.54 USDRegular priceUnit price / per -

1/32" Thick - 50A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $17.16 USDRegular priceUnit price / per -

1/32" Thick - 60A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $15.68 USDRegular priceUnit price / per -

1/32" Thick - 70A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $15.68 USDRegular priceUnit price / per -

1/16" Thick - 40A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $52.95 USDRegular priceUnit price / per -

1/16" Thick - 50A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $34.18 USDRegular priceUnit price / per -

1/16" Thick - 60A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $31.15 USDRegular priceUnit price / per -

1/16" Thick - 70A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $31.15 USDRegular priceUnit price / per -

3/32" Thick - 40A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $79.59 USDRegular priceUnit price / per -

3/32" Thick - 50A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $51.35 USDRegular priceUnit price / per -

3/32" Thick - 60A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $47.32 USDRegular priceUnit price / per -

3/32" Thick - 70A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $47.32 USDRegular priceUnit price / per -

1/8" Thick - 40A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $106.20 USDRegular priceUnit price / per -

1/8" Thick - 50A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $68.56 USDRegular priceUnit price / per -

1/8" Thick - 60A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $62.60 USDRegular priceUnit price / per -

1/8" Thick - 70A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $62.60 USDRegular priceUnit price / per -

3/16" Thick - 40A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $159.11 USDRegular priceUnit price / per -

3/16" Thick - 50A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $102.13 USDRegular priceUnit price / per -

3/16" Thick - 60A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $94.60 USDRegular priceUnit price / per -

3/16" Thick - 70A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $94.60 USDRegular priceUnit price / per -

1/4" Thick - 40A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $212.19 USDRegular priceUnit price / per -

1/4" Thick - 50A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $136.93 USDRegular priceUnit price / per -

1/4" Thick - 60A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $125.55 USDRegular priceUnit price / per -

1/4" Thick - 70A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $125.55 USDRegular priceUnit price / per -

5/16" Thick - 60A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $173.01 USDRegular priceUnit price / per -

3/8" Thick - 40A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $318.36 USDRegular priceUnit price / per -

3/8" Thick - 50A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $205.39 USDRegular priceUnit price / per -

3/8" Thick - 60A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $188.40 USDRegular priceUnit price / per -

3/8" Thick - 70A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $188.40 USDRegular priceUnit price / per -

1/2" Thick - 40A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $420.98 USDRegular priceUnit price / per -

1/2" Thick - 50A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $271.72 USDRegular priceUnit price / per -

1/2" Thick - 60A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $249.40 USDRegular priceUnit price / per -

1/2" Thick - 70A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $249.40 USDRegular priceUnit price / per -

5/8" Thick - 40A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $526.12 USDRegular priceUnit price / per -

5/8" Thick - 50A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $339.69 USDRegular priceUnit price / per -

5/8" Thick - 60A Durometer - Commercial Grade Black Neoprene Rubber

Regular price From $315.00 USDRegular priceUnit price / per

Table of Contents: Neoprene Rubber

- Neoprene Rubber: The Versatile Chloroprene Polymer for Demanding Applications

- Superior Properties of Neoprene Rubber That Make It Indispensable

- Neoprene Rubber Types: Solid, Closed Cell, and Specialized Formulations

- Neoprene Rubber Sheet Sizes, Thicknesses, and Customization Options

- Versatile Applications for Neoprene Rubber Sheets, Gaskets, and Seals

- How to Install Neoprene Rubber Sheets: Adhesives and Application Methods

- Neoprene Rubber Lifespan: Why Chloroprene Polymer Provides Long-Term Performance

- Frequently Asked Questions About Neoprene Rubber Sheets, Gaskets, and Applications

Neoprene Rubber: The Versatile Chloroprene Polymer for Demanding Applications

Neoprene (polychloroprene) is a highly versatile synthetic rubber developed as one of the first oil-resistant synthetic elastomers. Known for its exceptional balance of properties, neoprene rubber maintains its flexibility across a wide temperature range while offering outstanding resistance to oils, fuels, and many chemicals. This durable chloroprene polymer delivers consistent performance in demanding industrial, automotive, and marine environments where exposure to petroleum products is common. Whether you need neoprene rubber sheets, gaskets, or seals, this remarkable material provides reliable service in conditions that would quickly degrade many other elastomers.

Browse Additional Gasket Material Options

-

Viton® Rubber

Viton® Rubber Viton® Rubber Sheets Viton® Fluoroelastomer Premium Viton® rubber sheets now...

-

PTFE Sheets

PTFE Sheets Our premium PTFE sheets (also known as Teflon sheets) are...

-

Nitrile Rubber

Nitrile Rubber Our nitrile rubber is formulated for exceptional oil and chemical...

Superior Properties of Neoprene Rubber That Make It Indispensable

Neoprene rubber (polychloroprene) offers an exceptional combination of properties that make it ideal for numerous challenging applications:

- Oil and Fuel Resistance: Excellent resistance to petroleum products, lubricants, and hydraulic fluids

- Temperature Performance: Maintains flexibility and functionality from -40°F to +250°F

- Weather Resistance: Good resistance to ozone, UV radiation, and weathering effects

- Chemical Compatibility: Resistant to many moderate chemicals, acids, and bases

- Mechanical Strength: High tensile strength and tear resistance with good compression recovery

- Flame Retardance: Inherent flame-resistant properties make it suitable for safety applications

- Aging Stability: Maintains physical properties over extended periods even when exposed to harsh conditions

- Adhesion Properties: Excellent bond strength to metals and other substrates

These properties make neoprene rubber sheets and gasket material the preferred choice for applications requiring oil resistance combined with general environmental durability.

Comprehensive Rubber Solutions: Beyond Neoprene Sheets

-

Gasket Fabrication

Our precision gasket fabrication services transform neoprene and other rubber materials into custom-fit sealing solutions for any application. Using advanced cutting technologies and quality materials, we produce gaskets to your exact specifications with quick turnaround times. From simple washers to complex die-cut shapes, our fabrication capabilities ensure optimal performance and leak-free sealing for your most demanding projects.

-

Rubber Molding

Our rubber molding expertise allows us to create custom neoprene components with exceptional consistency and precision. We utilize compression, transfer, and injection molding techniques to produce complex shapes that maintain tight tolerances and superior performance characteristics. Whether you need small production runs or high-volume manufacturing, our molding capabilities deliver durable rubber parts that perfectly match your engineering requirements.

-

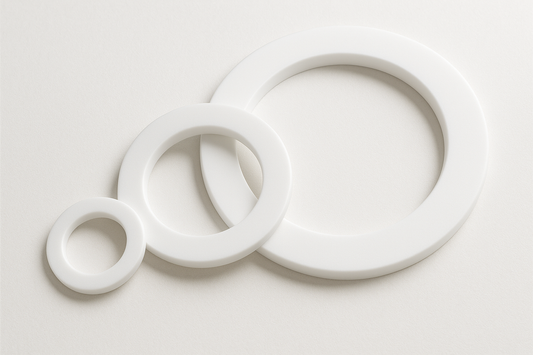

Lathe Cut Ring Gaskets

Our specialized lathe cutting technology produces precise neoprene ring gaskets with exceptional dimensional accuracy and clean edges. These precision-machined seals offer superior performance for critical applications in fluid handling, pressure vessels, and mechanical systems. Available in various cross-sections and diameters, our lathe cut rings provide reliable sealing solutions without the tooling costs associated with molded products.

Neoprene Rubber Types: Solid, Closed Cell, and Specialized Formulations

Neoprene rubber is available in several distinct forms, each engineered for specific performance requirements:

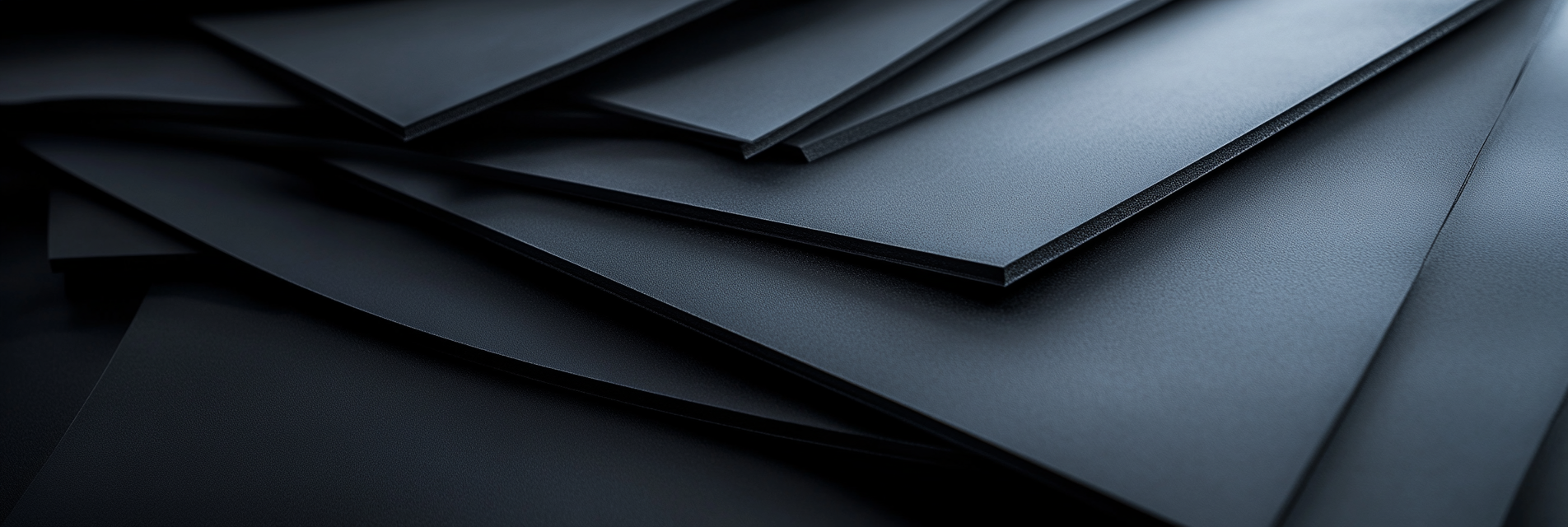

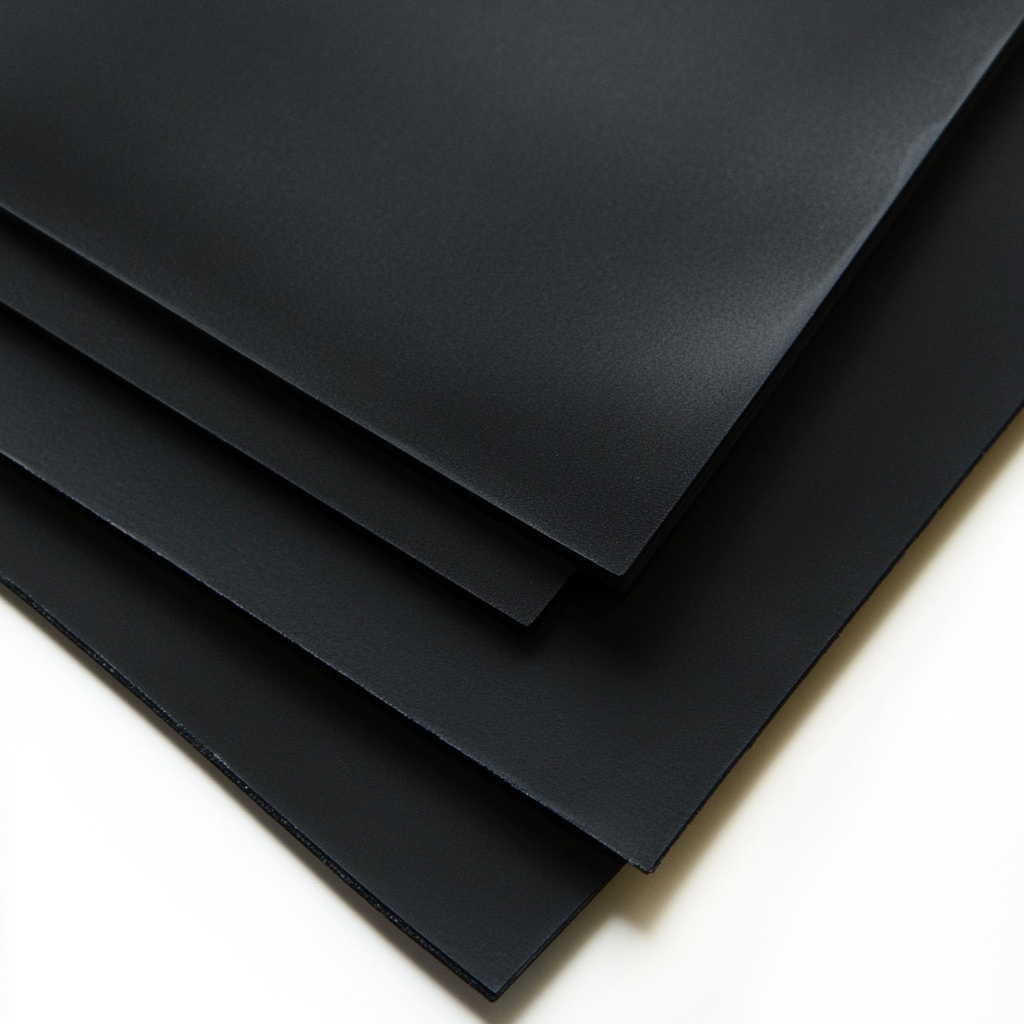

Solid Neoprene Rubber Sheets and Rolls

Solid neoprene is a dense, non-porous material offering maximum oil resistance, chemical compatibility, and mechanical strength. This form of chloroprene rubber provides superior impermeability to oils and fuels while maintaining excellent durability. Solid neoprene rubber is ideal for heavy-duty applications requiring maximum resistance to petroleum-based fluids, such as industrial gaskets, automotive seals, and chemical-resistant barriers.

Closed Cell Neoprene Foam

Closed cell neoprene foam features sealed air pockets within its structure, making it lightweight while maintaining excellent resistance to oils and water. This structure prevents fluid penetration while providing thermal and acoustic insulation. Closed cell neoprene rubber is perfect for gasket material in applications requiring compression recovery and insulation properties, such as automotive applications, marine hatch seals, and industrial cabinet seals.

Neoprene Blends and Specialized Formulations

For specific applications, neoprene is often blended with other polymers to enhance particular properties:

- CR/SBR blends for improved flexibility and cost-effectiveness

- CR/NBR combinations for extreme oil resistance

- Flame-retardant neoprene formulations for safety applications

Choosing between these neoprene rubber types depends on your specific requirements for oil resistance, temperature range, compression recovery, and environmental conditions.

Modern Rubber Products

1/16" Thick - 75A Durometer - Viton® Rubber

Share

Neoprene Rubber Sheet Sizes, Thicknesses, and Customization Options

Neoprene rubber sheets are available in various thicknesses and dimensions to meet diverse application requirements:

Solid Neoprene Rubber Sheet Thicknesses

Solid neoprene rubber sheets are available in a comprehensive range of thicknesses to suit virtually any application:

- 1/32" - Economical option for thin gaskets and liners in moderate conditions

- 1/16" - Popular for general-purpose industrial gaskets and seals

- 3/32" - Medium thickness offering balanced performance characteristics

- 1/8" - Standard for many industrial and automotive applications

- 3/16" - Enhanced durability for high-stress environments

- 1/4" - Heavy-duty applications requiring maximum strength and oil resistance

- 3/8" - Robust solution for high-compression and vibration applications

- 1/2" - Excellent for severe service conditions and impact absorption

- 5/8" - Superior performance in extreme mechanical environments

- 3/4" - High-performance thickness for the most demanding conditions

- 1" - Maximum thickness offering ultimate durability for specialized industrial uses

Closed Cell Neoprene Foam Dimensions

Closed cell neoprene foam sheets typically come in thicknesses from 1/16" to 1"+ thick, with standard sheet sizes of 36" or 40" width by 72" length. Custom cuts are available to meet specific requirements.

Neoprene Rubber Roll Options

Neoprene rubber rolls provide flexibility for covering larger areas and are available in various widths from 36" to 48" with lengths ranging from 10' to 50'.

Commercial and Industrial Grades

From commercial-grade neoprene (40-45 Shore A durometer) to specialized high-durometer formulations (70-80 Shore A), our neoprene rubber sheets and rolls are available in multiple hardness levels to match your application's requirements.

The cost of neoprene rubber sheets varies based on thickness and formulation, with specialized oil-resistant grades and thicker sheets commanding a premium price that is offset by their exceptional durability and performance.

Versatile Applications for Neoprene Rubber Sheets, Gaskets, and Seals

Neoprene (polychloroprene) rubber excels across numerous industries due to its exceptional combination of properties:

Automotive and Transportation

- Engine Gaskets: Neoprene gaskets provide reliable sealing in environments exposed to oils and fuels

- Hoses and Belts: Neoprene's oil and heat resistance make it ideal for fluid transfer components

- Vibration Isolation: Neoprene mounts and bushings absorb vibration while resisting degradation from lubricants

Industrial Applications

- Oil-Resistant Gaskets: Neoprene gasket material creates reliable seals in petroleum equipment

- Chemical Processing: Neoprene rubber sheets and linings protect against moderate chemical exposure

- Machinery Seals: Neoprene seals maintain integrity despite exposure to lubricants and hydraulic fluids

Marine and Outdoor Equipment

- Wet Suit Material: Neoprene's insulating properties and durability make it the standard for dive suits

- Hatch Seals: Neoprene rubber seals provide weather-tight barriers in marine environments

- Weather Stripping: Neoprene's resistance to weathering makes it ideal for outdoor equipment seals

Construction and Building

- Expansion Joint Covers: Neoprene's flexibility accommodates structural movement

- Vibration Isolation Pads: Neoprene's compression resistance provides long-term vibration control

- HVAC Gaskets: Neoprene gaskets maintain seals despite temperature fluctuations and exposure to oils

Electronics and Electrical

- Cable Jacketing: Neoprene's flexibility, durability, and moderate flame resistance protect wiring

- Electrical Enclosure Gaskets: Neoprene provides reliable environmental sealing for electrical cabinets

- Connector Seals: Neoprene's resilience ensures long-term sealing in challenging environments

From specialized oil-resistant formulations to standard commercial grades, neoprene rubber's versatility makes it essential across numerous industries requiring reliable performance in the presence of oils, moderate chemicals, and environmental challenges.

How to Install Neoprene Rubber Sheets: Adhesives and Application Methods

Proper installation of neoprene rubber sheets and gaskets ensures optimal performance and longevity:

Recommended Adhesives for Neoprene Rubber

For permanent bonding of neoprene rubber, several adhesive types provide excellent results:

- Polychloroprene (Contact) Adhesives: These solvent-based adhesives create an immediate bond with neoprene rubber and are ideal for large sheet applications

- Epoxy Adhesives: Two-part epoxies provide excellent chemical resistance and bond strength for structural applications

- Cyanoacrylate Adhesives: For small neoprene parts, these "super glues" create rapid bonds with good strength

Installation Process for Neoprene Rubber Sheets

- Surface Preparation: Clean all surfaces thoroughly to remove oils, dust, and contaminants

- Measuring and Cutting: Cut neoprene rubber sheets with a sharp utility knife or scissors, allowing slight excess for positioning

- Adhesive Application: For contact adhesives, apply to both surfaces and allow to become tacky; for epoxies, mix and apply per manufacturer's instructions

- Bonding: Join the surfaces carefully, as most adhesives will bond on contact

- Pressure Application: Apply even pressure across the entire bonded area using rollers or weights

- Curing: Allow the recommended curing time before subjecting the bond to stress or chemicals

Creating Neoprene Rubber Gaskets

When fabricating neoprene gaskets from sheet material:

- Create precise templates based on required dimensions

- Transfer patterns to neoprene rubber sheets using non-staining markers

- Cut neoprene carefully using appropriate tools (die cutters, water jet cutting, or precision knives)

- Verify gasket dimensions and hole alignments before installation

- Install using appropriate compression techniques or adhesives depending on the application

Neoprene Seals Installation Tips

For neoprene rubber seals in automotive or industrial applications:

- Ensure proper fit by measuring the gap precisely

- Select appropriate neoprene profile for the application

- Use specialized adhesives that maintain flexibility while resisting oils and solvents

- Test seal integrity before finalizing installation

Proper installation techniques are critical to maximize the oil resistance and durability characteristics that make neoprene rubber the preferred choice for demanding sealing applications.

The Rubber Blog: Tips, Trends & Technical Insights

View all-

What Are Urethane Sheets? Complete Guide to Pol...

What Are Urethane Sheets? Complete Guide to Polyurethane Material Urethane sheets are appearing in more industrial applications every year, but many professionals still wonder: what exactly are they, and why...

What Are Urethane Sheets? Complete Guide to Pol...

What Are Urethane Sheets? Complete Guide to Polyurethane Material Urethane sheets are appearing in more industrial applications every year, but many professionals still wonder: what exactly are they, and why...

-

What is PTFE Sheets: The Complete Guide to Poly...

Complete guide to PTFE sheets properties, universal chemical resistance, and applications. Learn about Teflon specifications for pharmaceutical, food processing, and chemical manufacturing sealing.

What is PTFE Sheets: The Complete Guide to Poly...

Complete guide to PTFE sheets properties, universal chemical resistance, and applications. Learn about Teflon specifications for pharmaceutical, food processing, and chemical manufacturing sealing.

-

What is Viton Rubber: The Complete Guide to Flu...

Complete guide to Viton rubber properties, chemical resistance, and high-temperature applications. Learn about fluoroelastomer specifications for chemical processing, aerospace, and extreme environment sealing.

What is Viton Rubber: The Complete Guide to Flu...

Complete guide to Viton rubber properties, chemical resistance, and high-temperature applications. Learn about fluoroelastomer specifications for chemical processing, aerospace, and extreme environment sealing.

Neoprene Rubber Lifespan: Why Chloroprene Polymer Provides Long-Term Performance

The exceptional durability of neoprene rubber makes it a cost-effective choice for applications exposed to oils and challenging environments:

Expected Lifespan of Neoprene Rubber

When properly installed and maintained, neoprene rubber products typically last:

- 15-25 years for neoprene seals in automotive applications

- 20-30 years for industrial gaskets in controlled environments

- 10-15 years for outdoor applications with direct environmental exposure

This impressive longevity stems from the inherent stability of the polychloroprene polymer structure.

Factors Affecting Neoprene Rubber Longevity

Several factors influence how long neoprene rubber sheets and products will maintain their performance:

- Chemical Exposure: Concentrated acids, strong oxidizing agents, and some ketones can accelerate degradation

- Temperature Extremes: While neoprene performs well from -40°F to +250°F, constant exposure near these limits may reduce lifespan

- Compression Set: Permanent compression beyond design parameters can affect seal performance over time

- Oil Type: While resistant to most petroleum products, some synthetic oils and additives may cause swelling

Maintaining Neoprene Rubber Products

To maximize the lifespan of neoprene rubber:

- Regularly inspect for signs of hardening, cracking, or permanent deformation

- Clean with mild detergent and water, avoiding harsh solvents

- Prevent unnecessary exposure to direct sunlight and extreme heat

- Apply silicone-based rubber protectants for exposed outdoor applications

The exceptional oil resistance and environmental durability of neoprene rubber provide outstanding value over time, particularly in applications where exposure to petroleum products would quickly degrade alternative elastomers.

Frequently Asked Questions About Neoprene Rubber Sheets, Gaskets, and Applications

Is neoprene rubber resistant to gasoline and diesel fuel?

Neoprene offers good resistance to brief exposure to fuels and oils. While it provides better fuel resistance than many elastomers (like EPDM), for prolonged immersion in gasoline or diesel, specialized fuel-resistant elastomers like Viton® may be recommended. Neoprene is ideal for splash exposure and vapor environments involving petroleum products.

What is the difference between neoprene and natural rubber?

While both offer good flexibility and elongation, neoprene provides superior resistance to oils, fuels, and many chemicals, along with better aging stability and heat resistance. Natural rubber offers higher elasticity and tear strength but degraded rapidly when exposed to petroleum products. Neoprene is preferred for applications involving oils, while natural rubber excels in pure mechanical applications.

Can neoprene rubber be used outdoors?

Yes, neoprene has good resistance to weathering, UV exposure, and ozone, making it suitable for outdoor applications. While not as weather-resistant as EPDM, neoprene maintains its properties well in outdoor environments, especially when compared to elastomers like nitrile rubber. For maximum lifespan in outdoor applications, protective coatings can further enhance its weather resistance.

How do you clean neoprene rubber?

For regular maintenance, clean neoprene with mild soap and water. For oil contamination, use a mild degreasing detergent followed by a thorough water rinse. Avoid harsh solvents like acetone or MEK, which can damage the material. For disinfection, a dilute bleach solution (1:10) is generally safe for brief exposure, followed by thorough rinsing.

What temperatures can neoprene rubber withstand?

Neoprene rubber typically performs well in temperatures ranging from -40°F to +250°F (-40°C to +121°C). It maintains flexibility at lower temperatures better than many oil-resistant elastomers and offers good heat resistance for moderate applications. For extreme temperature applications, specialized high-temperature or low-temperature neoprene formulations are available.

Is neoprene environmentally friendly?

Standard neoprene is not biodegradable, but it is extremely durable, which reduces replacement frequency and associated waste. Neoprene's long service life makes it environmentally favorable from a lifecycle perspective. Additionally, neoprene products can often be recycled at specialized facilities, particularly from large-scale applications like wetsuits or industrial belting.

How does neoprene compare to nitrile rubber?

While both offer good oil resistance, nitrile (NBR) provides superior resistance to oils, fuels, and hydrocarbons but has less flexibility in cold temperatures and poorer resistance to ozone and weathering. Neoprene offers better overall environmental resistance, flexibility across a wider temperature range, and superior flame retardance. Choose nitrile for applications requiring maximum oil resistance, and neoprene for applications requiring a balance of oil resistance and environmental durability.

Understanding these aspects of chloroprene rubber helps ensure you select the right neoprene rubber sheets, gaskets, or seals for your specific application requirements, particularly in environments where exposure to petroleum products is a concern.