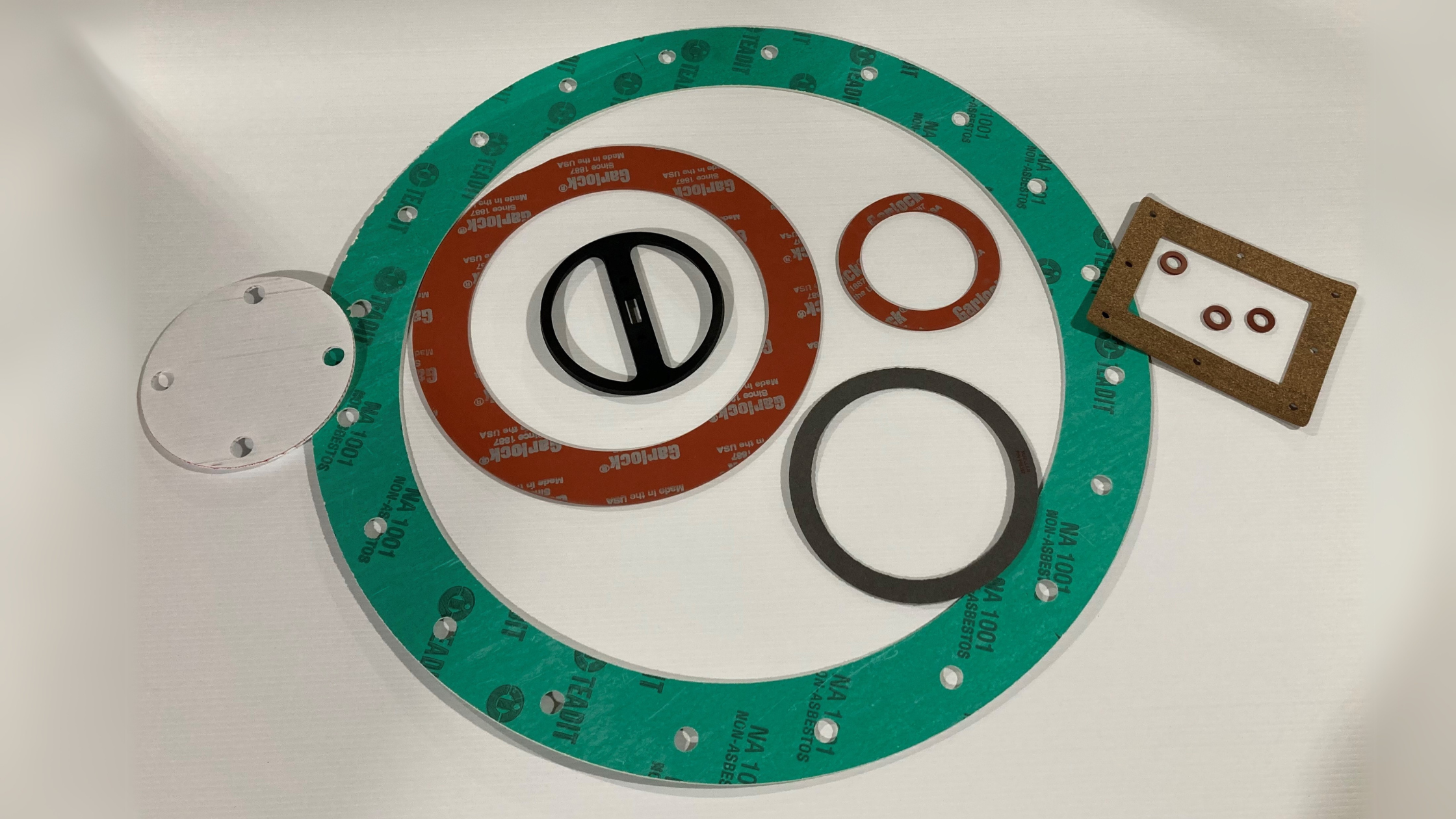

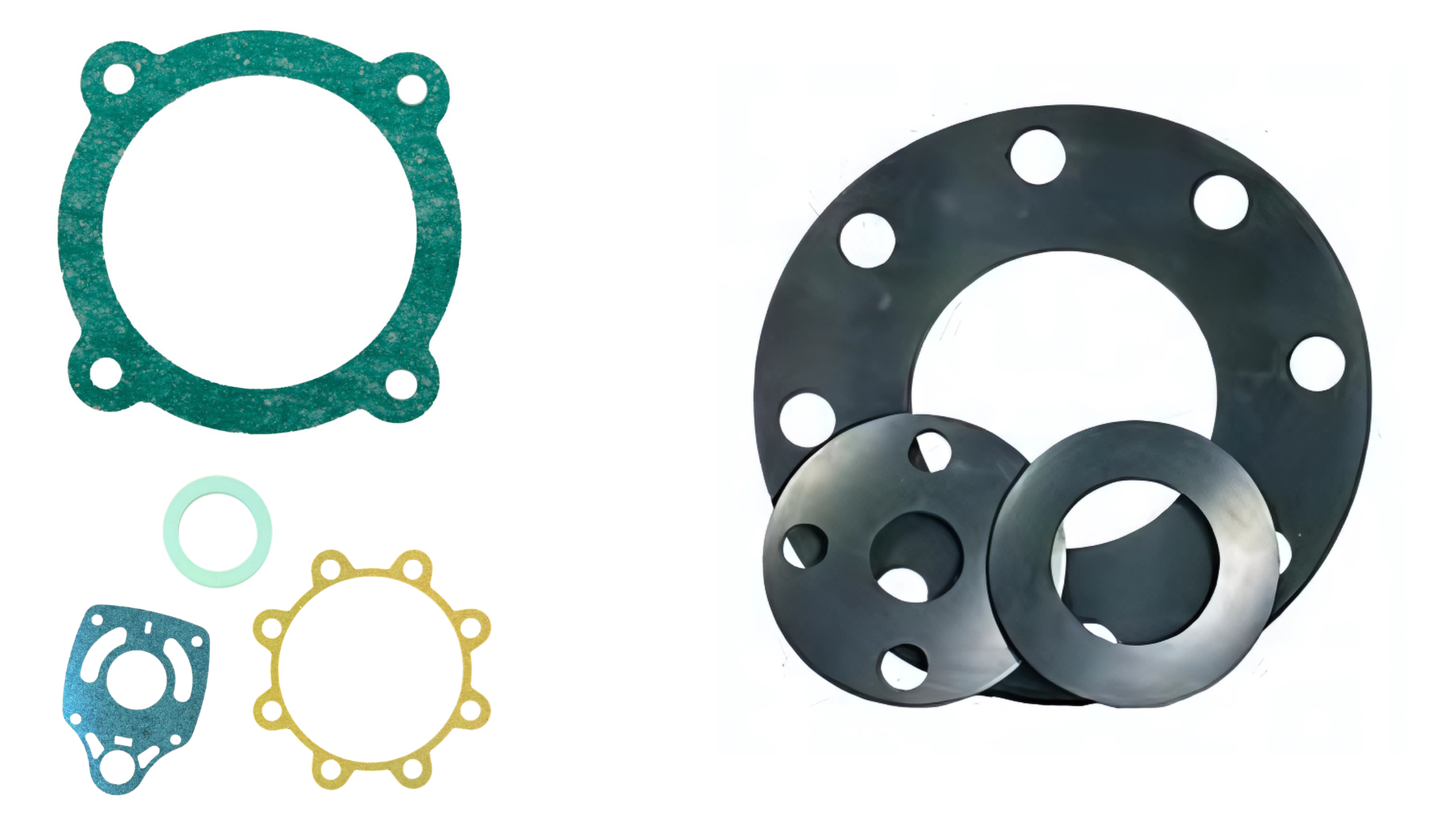

custom rubber components

Die Cut Parts

At Modern Rubber Products, die cutting has been the foundation of our business since our inception. While we've expanded our capabilities significantly, die cutting remains one of our core competencies alongside our rubber molding services.

Our Cutting Technologies

We utilize three distinct cutting technologies to ensure we can meet any manufacturing challenge:

Toolless Knife Cutters (Flash Cutters)

- Rapid production with no tooling requirements

- Ideal for both high-volume production and prototyping

- Advanced nesting software maximizes material utilization

- Reduces waste and lowers part costs

- Quick turnaround times

Traveling Head Stamping Presses

- Superior precision for tight tolerance requirements

- Excellent for complex geometries and shapes

- Versatile production volumes

- Uses economical steel rule dies

- Consistent part quality

Waterjet Cutting

- Cuts materials up to 4" thick

- Handles high durometer materials (95 Shore A and above)

- Extremely precise with tight tolerances

- Produces clean cut edges with minimal flash

- Ideal for thick rubber and hard durometer materials

Material Capabilities

We process a wide range of materials to meet diverse industrial needs:

Rubber Materials

- Nitrile

- EPDM

- Neoprene

- SBR

- Silicone

- Viton

- Cloth Inserted Fiber Materials

- Aflac

- Gum Rubber

- Materials up to 95 durometer Shore A

Plastics

- PTFE/Teflon

- UHMW

- HDPE

- Acetal

- Delrin

Compressed Fiber Materials

We work with all leading brands including:

- Garlock

- Klinger

- Durlon

- Teadit

Our Manufacturing Approach

We analyze each project individually to determine the optimal manufacturing method based on:

- Material type and specifications

- Durometer/hardness requirements

- Material thickness

- Production volume

- Part geometry

- Tolerance requirements

- Cost efficiency goals

Why Choose Us for Die Cut Parts?

Our diverse cutting technologies allow us to optimize your manufacturing process based on your specific needs.

Whether you require:

High-volume production

Prototype development

Tight tolerances

Complex geometries

Thick or hard materials

Cost-effective solutions

We have the expertise and equipment to deliver superior results while maintaining competitive pricing through efficient material utilization and appropriate technology selection.

From Simple Gaskets to Complex Seals

Over 50 Years of Die Cut Excellence

From Simple Gaskets to Complex Seals

Over 50 Years of Die Cut Excellence

From Simple Gaskets to Complex Seals

Over 50 Years of Die Cut Excellence

From Simple Gaskets to Complex Seals

Over 50 Years of Die Cut Excellence