PUMPING & PLUMBING INDUSTRY

Pumping & Plumbing Systems Industry Solutions

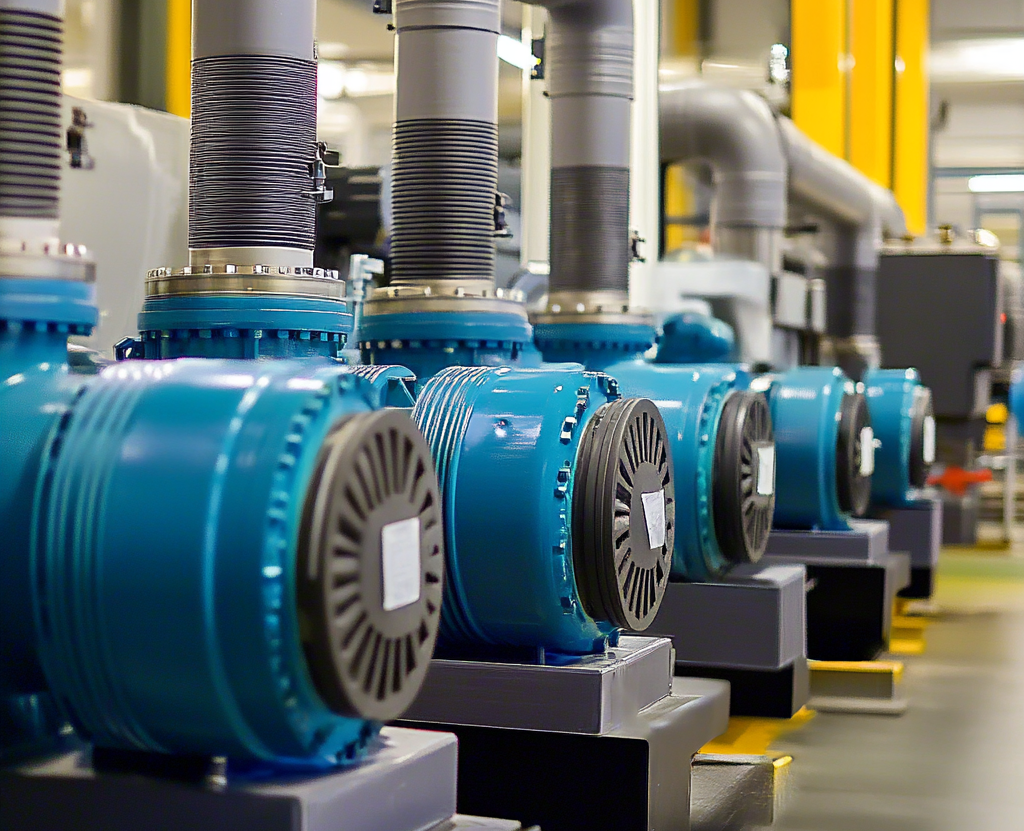

Modern Rubber Products delivers specialized sealing components engineered for the critical requirements of industrial and commercial pumping and plumbing systems. Our precision-manufactured gaskets, seals, and custom rubber components are designed to withstand constant fluid contact, pressure fluctuations, and the diverse chemical environments encountered in fluid handling applications. We provide reliable rubber solutions for water distribution, wastewater management, chemical transfer, and specialized fluid processing that prevent leakage while ensuring system efficiency and regulatory compliance. Our Chattanooga manufacturing facility employs advanced fabrication techniques to create components that maintain integrity despite challenging operating conditions while extending equipment life in essential pumping and plumbing infrastructure.

Critical Pumping & Plumbing Applications

Our rubber components serve essential functions throughout fluid handling systems, including:

- Pump housing gaskets and mechanical seal components

- Valve seat seals and stem packing for flow control

- Flange gaskets for pipe connections and equipment interfaces

- Expansion joints for thermal movement compensation

- Diaphragms for metering and control applications

- Check valve and backflow prevention components

- Custom molded seals for specialized equipment

- Vibration isolation mounts for pumping equipment

Rubber Engineered for Fluid System Performance

Modern Rubber Products manufactures a comprehensive range of sealing solutions specifically designed for pumping and plumbing operations. Our components are produced using materials selected for their documented performance in continuous fluid contact applications. We utilize advanced elastomers including EPDM, FKM (Viton®), nitrile, and specialized compounds formulated to withstand water, chemicals, and the pressure conditions found in modern fluid handling systems. Our engineering team ensures each component meets industry specifications while delivering reliable performance in critical applications where leakage is not an option.

Meeting the Unique Challenges of Fluid Handling

Pumping and plumbing applications present distinct demands for rubber components, requiring materials and designs that ensure both reliability and compliance with various fluid regulations. At Modern Rubber Products, we understand these specialized needs:

Material Selection for Fluid Compatibility

Fluid handling systems require rubber components formulated specifically for the media being processed. Our pumping and plumbing industry products are manufactured using compounds specifically selected to withstand:

- Continuous water contact in potable and non-potable applications

- Aggressive chemicals in industrial process systems

- Temperature variations from cryogenic to high-temperature fluids

- Pressure cycling and water hammer conditions

- Abrasive slurries and particle-laden fluids

- Specialized oils and synthetic fluids in hydraulic systems

Precision Manufacturing for System Integrity

Pumping components must provide reliable sealing under dynamic operating conditions. Our manufacturing capabilities, including compression molding and waterjet cutting, produce components with exact specifications and tolerances required for proper installation in centrifugal pumps, positive displacement pumps, control valves, and piping systems throughout fluid handling applications.

Certifications for Regulated Applications

Pumping and plumbing systems often operate under strict regulatory requirements. Our manufacturing processes and material selections support compliance with relevant standards including:

- NSF/ANSI 61 for potable water contact

- FDA 21 CFR 177.2600 for food processing applications

- ASTM specifications for flange gaskets and sealing elements

- USP Class VI for pharmaceutical fluid handling

- 3-A Sanitary Standards for dairy and beverage processing

Specialized Solutions for Industrial Process Pumping

Modern Rubber Products supports the specialized needs of industrial process pumping with components designed for challenging fluid applications. Our process pump offerings include:

- Chemical transfer pump seals with superior chemical resistance

- Abrasion-resistant slurry pump components

- High-temperature heat transfer fluid pump seals

- Sanitary pump gaskets for food and pharmaceutical applications

- Custom engineered sealing systems for specialized pumping equipment

Our engineering team works closely with pump manufacturers and maintenance professionals to develop sealing solutions that address the unique challenges of specific fluid handling applications while maximizing equipment uptime and operational efficiency.

Pumping & Plumbing Industry FAQs

What rubber materials are best suited for water pump applications?

For standard water pumping applications, we typically recommend EPDM compounds for their excellent resistance to water, steam, and water treatment chemicals. For applications involving hydrocarbon exposure or certain oils, we offer specialized nitrile (NBR) compounds. High-performance pumps operating at elevated temperatures often utilize FKM (Viton®) components for extended service life. Our engineering team can help select the optimal material based on your specific operating conditions, temperature range, and chemical exposure.

Can you provide custom gaskets that meet specific flange standards?

Yes, we manufacture gaskets conforming to all major flange standards including ANSI, DIN, JIS, and specialized configurations. Our waterjet cutting capabilities allow us to produce precise gaskets for any flange class, pressure rating, or pipe size. We can work from standard specifications or custom drawings to create exact replacements for your specific equipment, often with same-day or next-day turnaround for emergency repair situations.

What is the typical lead time for pump and valve sealing components?

For standard pump gaskets and valve seals, we can typically fulfill orders within 1-2 weeks. Components requiring specialized fluid-resistant compounds may require 2-3 weeks. Custom molded components for unique applications require additional time for tooling development, with typical lead times of 8-10 weeks for initial production. We understand the critical nature of fluid system operations and can expedite orders for emergency maintenance situations.

Do you offer materials that comply with drinking water standards?

Yes, we provide NSF/ANSI 61 certified compounds for potable water applications in municipal water systems, building plumbing, and food/beverage processing. These materials maintain their mechanical properties while ensuring no harmful substances leach into drinking water. Our quality control processes ensure full traceability and documentation as required for potable water applications.