HYDRAULICS INDUSTRY

Hydraulic Systems Industry Solutions

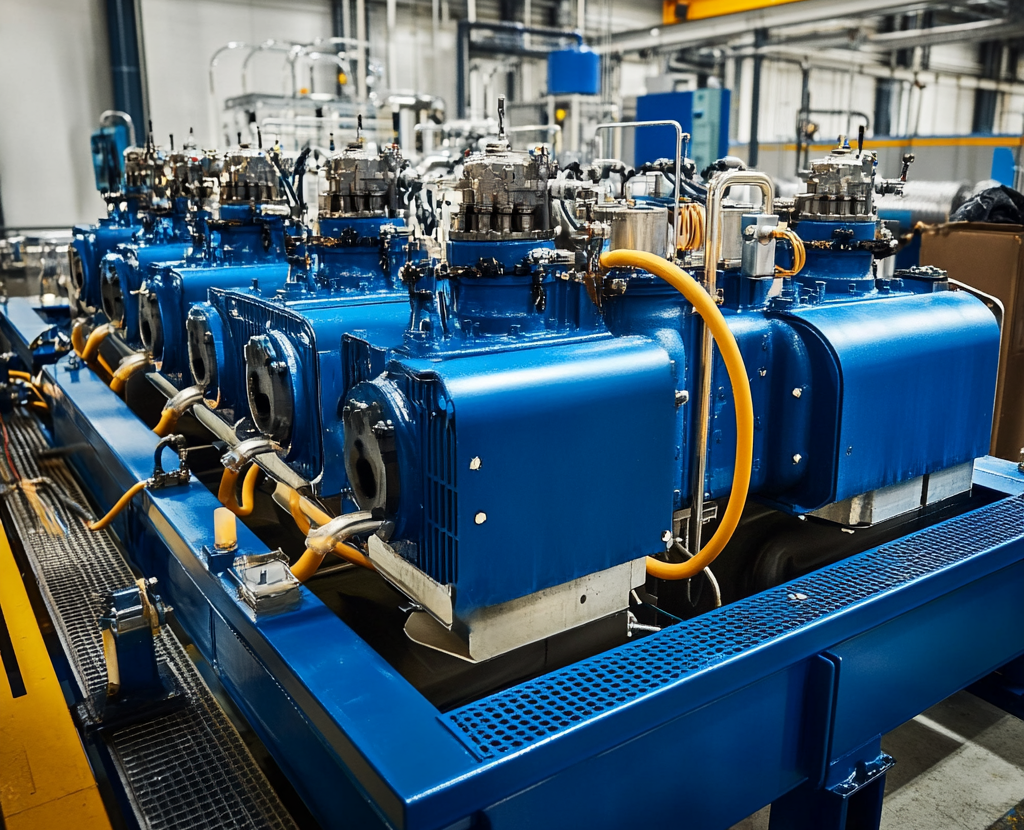

Modern Rubber Products delivers specialized sealing components engineered for the extreme pressure demands of hydraulic systems. Our high-performance gaskets, seals, and custom rubber components are designed to withstand intense pressure, temperature fluctuations, and exposure to hydraulic fluids encountered in industrial machinery, mobile equipment, and precision control systems. We provide reliable rubber solutions that prevent leakage while maintaining system efficiency and operational safety in critical hydraulic applications. Our Chattanooga manufacturing facility employs advanced fabrication techniques to create components that ensure fluid containment despite challenging operating conditions while extending equipment life in essential hydraulic infrastructure.

Critical Hydraulic System Applications

Our rubber components serve essential functions throughout hydraulic systems, including:

- Cylinder head seals and rod wipers

- Piston seals and O-rings for actuators

- Accumulator bladders and diaphragms

- Valve stem seals and body gaskets

- Pump shaft seals and housing gaskets

- Fluid reservoir seals and breather elements

- Hydraulic hose connections and fitting seals

- Custom molded components for specialized equipment

Rubber Engineered for Hydraulic Performance

Modern Rubber Products manufactures a comprehensive range of sealing solutions specifically designed for hydraulic system requirements. Our components are produced using materials selected for their documented performance under high-pressure conditions. We utilize advanced elastomers including polyurethane, nitrile (NBR), hydrogenated nitrile (HNBR), FKM (Viton®), and specialized compounds formulated to withstand hydraulic fluids, pressure spikes, and the dynamic conditions found in modern hydraulic systems. Our engineering team ensures each component meets industry specifications while delivering reliable performance in critical applications where system pressure integrity is paramount.

Meeting the Unique Challenges of Hydraulic Systems

Hydraulic applications present some of the most demanding environments for rubber components, requiring materials and designs that ensure both pressure resistance and dynamic sealing capabilities. At Modern Rubber Products, we understand these specialized needs:

Material Selection for Hydraulic Performance

Hydraulic systems involve unique challenges for elastomer components. Our hydraulic industry products are manufactured using compounds specifically formulated to withstand:

- Extreme system pressures up to 10,000 PSI

- Hydraulic fluid compatibility with minimal swelling

- Temperature fluctuations from cold starts to operating temperatures

- Abrasive contamination in hydraulic media

- Extrusion resistance under pressure cycling

- Dynamic motion in actuator and cylinder applications

Precision Manufacturing for Pressure Integrity

Hydraulic components must provide reliable sealing under extreme pressure conditions. Our manufacturing capabilities, including precision molding and CNC machining, produce components with exact specifications and tolerances required for proper installation in cylinders, pumps, valves, and specialized hydraulic equipment.

Material Testing for System Compatibility

Hydraulic system reliability depends on proper material selection. Our quality assurance processes include:

- Compatibility testing with common hydraulic fluids

- Pressure cycle testing for seal integrity

- Compression set testing for long-term performance

- Temperature stability evaluation

- Abrasion resistance verification

- Custom testing protocols for specialized applications

Specialized Solutions for Advanced Hydraulic Applications

Modern Rubber Products supports the evolution of hydraulic technology with specialized components designed for emerging applications. Our advanced hydraulic offerings include:

- High-pressure water hydraulic system seals

- Sealing solutions for electro-hydraulic actuators

- Low-friction seals for energy-efficient systems

- Fire-resistant fluid compatible elastomers

- Custom engineered seals for extreme pressure applications

Hydraulic Industry FAQs

What rubber materials provide the best performance in hydraulic cylinders?

For dynamic hydraulic cylinder applications, we typically recommend polyurethane compounds for their exceptional wear resistance, pressure capabilities, and excellent mechanical properties. For static sealing applications, nitrile (NBR) and hydrogenated nitrile (HNBR) provide excellent fluid compatibility with standard hydraulic oils. For high-temperature applications or exposure to specialized hydraulic fluids, we offer FKM (Viton®) compounds. The optimal material depends on your specific pressure requirements, cylinder design, and operating conditions.

Can you provide seals that prevent hydraulic fluid leakage in high-cycle applications?

Yes, we specialize in developing sealing solutions for high-cycle hydraulic applications where conventional seals might fail prematurely. Our engineered sealing systems include special profile designs that minimize friction while maximizing sealing efficiency, advanced materials with superior abrasion resistance, and buffer seals that protect primary seals from pressure spikes. We work closely with hydraulic system designers to create custom solutions for the most demanding cyclic applications.

Do you offer materials compatible with biodegradable hydraulic fluids?

Yes, we provide specialized compounds formulated specifically for compatibility with environmentally friendly hydraulic fluids, including vegetable-based oils and synthetic biodegradable formulations. These materials maintain their sealing integrity while resisting the different solvency characteristics of bio-fluids that can cause premature failure in conventional sealing materials. Our engineering team can recommend the optimal compound based on your specific fluid type and operating conditions.

How do your products help prevent catastrophic hydraulic system failures?

Our precision-manufactured sealing solutions help prevent sudden failures through engineered design features including extrusion resistance, buffer seal arrangements, and materials selected for their ability to maintain integrity even under abusive conditions. We can incorporate visual wear indicators, controlled leakage paths to prevent catastrophic failures, and specialized compounds that resist explosive decompression. Our engineering team works with hydraulic system designers to identify critical sealing points and recommend optimal materials and designs for maximum system reliability.