HVAC INDUSTRY

HVAC Industry Solutions

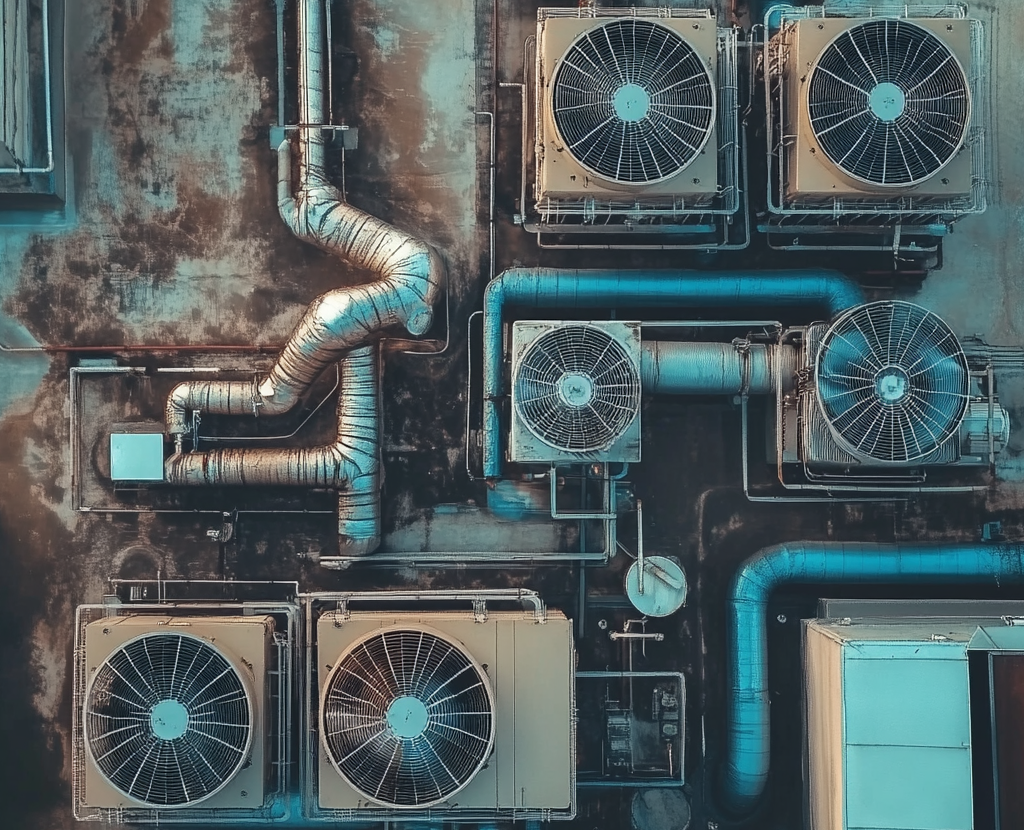

Modern Rubber Products provides specialized sealing components engineered for heating, ventilation, air conditioning, and refrigeration systems. Our custom gaskets, seals, and rubber components are designed to withstand the temperature extremes, pressure differentials, and diverse environmental conditions encountered in HVAC applications. We deliver rubber solutions for residential, commercial, and industrial HVAC equipment that ensure system efficiency, prevent air and fluid leakage, and maintain reliable operation throughout extended service life. Our Chattanooga manufacturing facility employs precision fabrication techniques to produce components that meet exact specifications while supporting energy efficiency goals and regulatory compliance for modern climate control systems.

Critical HVAC Applications

Our rubber components serve essential functions throughout HVAC systems, including:

- Air handler unit gaskets and mounting pads

- Ductwork sealing components and vibration isolators

- Refrigeration system seals and valve components

- Chiller and cooling tower gaskets and seals

- Pump and compressor sealing systems

- Expansion joints for thermal movement

- Fan and blower vibration isolation mounts

- Custom fabricated components for specialized equipment

Rubber Engineered for Climate Control Performance

Modern Rubber Products manufactures a comprehensive range of sealing solutions specifically designed for HVAC and refrigeration applications. Our components are produced using materials selected for their documented performance in both high and low-temperature extremes. We utilize advanced elastomers including EPDM, neoprene, silicone, and specialized compounds formulated to withstand refrigerants, oils, and the temperature cycling inherent in climate control systems. Our engineering team ensures each component meets equipment manufacturers' specifications while delivering consistent performance throughout the operational life of the system.

Meeting the Unique Challenges of HVAC Systems

HVAC applications present distinct demands for rubber components, requiring materials and designs that ensure both reliability and energy efficiency. At Modern Rubber Products, we understand these specialized needs:

Material Selection for Temperature Extremes

Climate control systems require rubber components that maintain their properties despite significant temperature variations. Our HVAC industry products are manufactured using compounds specifically formulated to withstand:

- Low temperatures in refrigeration and cooling systems

- High temperatures in heating equipment and compressors

- Rapid temperature fluctuations during cycling operations

- Refrigerant and oil exposure in sealed systems

- UV and ozone exposure for outdoor equipment

Precision Manufacturing for System Efficiency

HVAC components must provide reliable sealing to maintain system efficiency and performance. Our manufacturing capabilities, including waterjet cutting and die cutting, produce components with exact specifications and tolerances required for proper installation in air handlers, ductwork, refrigeration equipment, and specialized climate control systems.

Energy Efficiency Through Proper Sealing

HVAC system efficiency depends significantly on proper sealing throughout air and fluid pathways. Our solutions are engineered for exceptional sealing performance with properties including:

- Excellent compression set resistance for maintained sealing force

- Low air permeability for reduced system leakage

- Thermal insulation properties where required

- Resilience for repeated assembly and disassembly

- Compatibility with HVAC lubricants and chemicals

Specialized Solutions for Energy Recovery Systems

Modern Rubber Products supports the growing demand for energy recovery ventilation (ERV) and heat recovery systems with specialized components designed for these efficiency-focused applications. Our offerings include:

- Custom gaskets for energy recovery ventilators and heat exchangers

- Sealing systems for enthalpy wheels and heat recovery cores

- Condensation-resistant materials for moisture transfer applications

- Specialized components for demand-controlled ventilation systems

Our engineering team works closely with HVAC equipment manufacturers to develop sealing solutions that support the increased efficiency demands of modern green building standards and energy codes.

HVAC Industry FAQs

What rubber materials are best suited for refrigeration systems?

For refrigeration systems, we typically recommend specialized compounds including certain HNBR and neoprene formulations specifically designed for refrigerant and oil compatibility. These materials maintain their sealing properties at the low temperatures found in refrigeration while resisting swelling and degradation from refrigerant exposure. For systems using newer refrigerants, we offer specialized compounds tested for compatibility with HFO and other alternative refrigerants.

Can you provide custom gaskets for air handling equipment?

Yes, our waterjet and die cutting capabilities allow us to produce custom gaskets for any air handling unit or ductwork application, from standard flanges to proprietary equipment connections. We can work from your drawings or reverse-engineer existing components to create precise replacements, helping to eliminate air leakage that reduces system efficiency and increases operating costs.

What is the typical lead time for HVAC rubber components?

For standard HVAC materials like EPDM and neoprene gaskets, we can typically fulfill orders within a few days from our inventory. Custom-cut gaskets generally require 1-2 weeks depending on complexity and quantity. Specialized molded components for unique applications require additional time for tooling development, with typical lead times of 8-10 weeks for initial production. We understand the seasonal nature of HVAC work and can expedite orders during peak demand periods.

How do your products help reduce HVAC system noise and vibration?

We manufacture a variety of vibration isolation components including rubber mounts, pads, and bushings specifically designed to minimize the transmission of equipment vibration to building structures. These components are formulated with specific durometer hardnesses and deflection characteristics to dampen vibrations at the frequencies commonly generated by HVAC equipment, reducing noise complaints and improving occupant comfort.