ELECTRONICS INDUSTRY

Electronics Manufacturing Industry Solutions

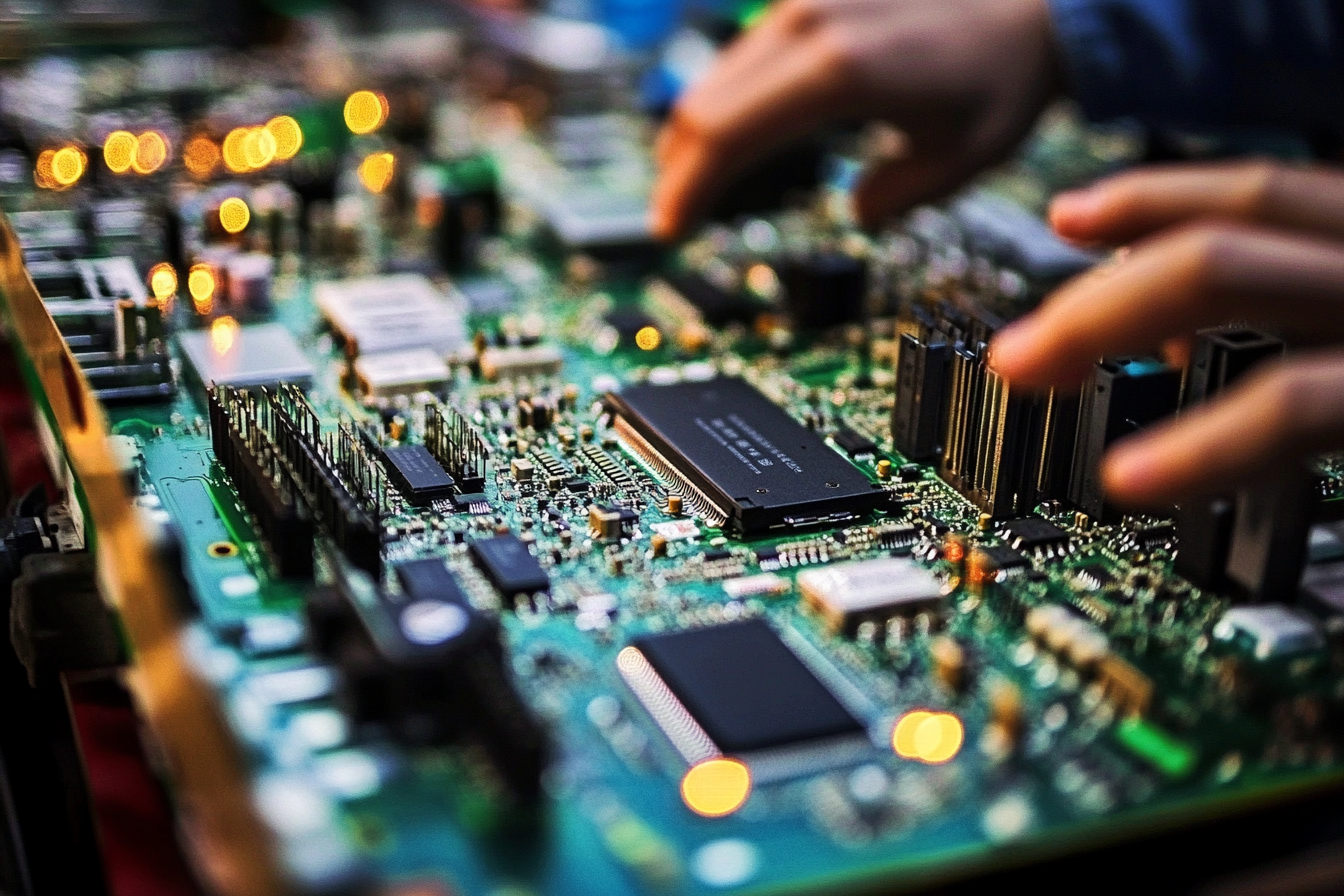

Modern Rubber Products delivers precision-engineered sealing and insulating components critical to the electronics manufacturing sector. Our specialized rubber materials and components are designed to provide electromagnetic interference (EMI) shielding, environmental protection, and electrical insulation for sensitive electronic assemblies. We supply rubber solutions for consumer electronics, industrial control systems, telecommunications equipment, and advanced electronic devices that ensure reliable operation while meeting strict dimensional tolerances. Our Chattanooga manufacturing facility employs advanced fabrication techniques to create components that provide essential protection against moisture, dust, and environmental contaminants while maintaining the precision required for today's miniaturized electronic applications.

Critical Electronics Manufacturing Applications

Our rubber components serve essential functions throughout electronic devices and manufacturing processes, including:

- EMI/RFI shielding gaskets and conductive elastomers

- Environmental seals for enclosures and housings

- Vibration isolation mounts for sensitive components

- Thermal interface pads for heat management

- Button and keypad components for user interfaces

- Cable grommets and strain relief elements

- Custom molded seals for connector assemblies

- Waterproofing gaskets for portable devices

Rubber Engineered for Electronic System Performance

Modern Rubber Products manufactures a comprehensive range of sealing solutions specifically designed for electronics manufacturing requirements. Our components are produced using materials selected for their electrical properties, dimensional stability, and performance in electronics applications. We utilize specialized elastomers including silicone, EPDM, fluorosilicone, and conductive compounds formulated to meet the exacting standards of electronic device manufacturers. Our engineering team ensures each component meets specifications for both electrical and mechanical performance while supporting the miniaturization trends of modern electronics.

Meeting the Unique Challenges of Electronics Manufacturing

Electronics applications present unique demands for rubber components, requiring materials and designs that ensure both electrical performance and environmental protection. At Modern Rubber Products, we understand these specialized needs:

Material Selection for Electronic Applications

Electronics require rubber components with specific electrical and mechanical properties. Our electronics industry products are manufactured using compounds specifically formulated to provide:

- Electrical insulation with controlled resistivity

- Conductive pathways for EMI/RFI shielding

- Thermal conductivity for heat dissipation

- Low outgassing for sensitive components

- Flame retardant properties for safety compliance

- Chemical resistance to cleaning agents and process chemicals

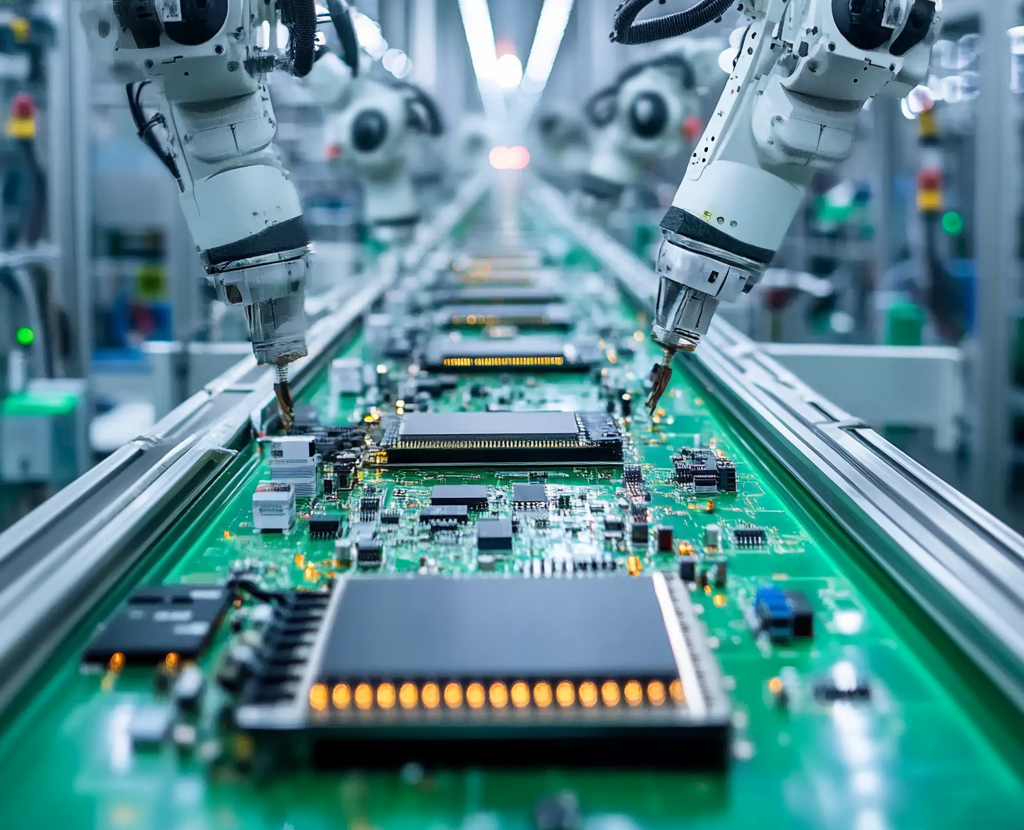

Precision Manufacturing for Miniaturized Components

Electronic components require extremely tight dimensional tolerances. Our manufacturing capabilities, including precision die cutting and micro-molding, produce components with exact specifications required for proper integration into compact electronic assemblies, automated manufacturing processes, and high-density applications.

Regulatory Compliance for Global Markets

Electronics manufacturing must meet numerous international standards. Our materials and manufacturing processes support compliance with relevant regulations including:

- UL 94 flame ratings for electronic components

- RoHS and REACH requirements for hazardous substances

- IP rating standards for environmental protection

- Military specifications for defense applications

- ISO 10993 for medical electronic devices

- Low outgassing specifications for sensitive applications

Specialized Solutions for Advanced Electronics

Modern Rubber Products supports the rapidly evolving electronics industry with specialized components designed for emerging technologies. Our advanced electronics offerings include:

- Thermal interface materials for high-performance computing

- Ultra-thin gaskets for next-generation mobile devices

- Optical-grade transparent elastomers for display applications

- Low-outgassing compounds for sensor applications

- Custom materials for flexible and wearable electronics

Electronics Manufacturing Industry FAQs

What rubber materials offer the best EMI/RFI shielding performance?

For electromagnetic interference shielding, we offer specialized conductive elastomers including silicone and fluorosilicone compounds loaded with conductive fillers such as silver, nickel-graphite, silver-aluminum, and carbon. The optimal material depends on your specific shielding requirements, frequency range, and environmental exposure conditions. Our engineering team can recommend the appropriate compound and design based on your attenuation requirements and application constraints.

Can you provide gaskets with precise dimensional tolerances for miniaturized electronics?

Yes, our precision die cutting and waterjet cutting capabilities allow us to produce gaskets and seals with tolerances as tight as ±0.005" for critical electronic applications. For ultra-precise requirements, we employ vision systems and automated inspection to ensure dimensional accuracy critical for high-density electronic assemblies. We can work from your CAD drawings to create exact components that integrate seamlessly with automated assembly processes.

Do you offer materials suitable for high-temperature electronic applications?

Yes, we provide specialized high-temperature compounds, particularly silicone formulations rated for continuous service at temperatures up to 500°F (260°C). These materials maintain their physical properties and sealing capabilities even in the elevated temperatures encountered in power electronics, LED lighting systems, and high-performance computing applications. For extreme temperature applications, we can recommend specialized compounds with appropriate fillers and cure systems.