APPLIANCE MANUFACTURING INDUSTRY

Appliance Manufacturing Industry Solutions

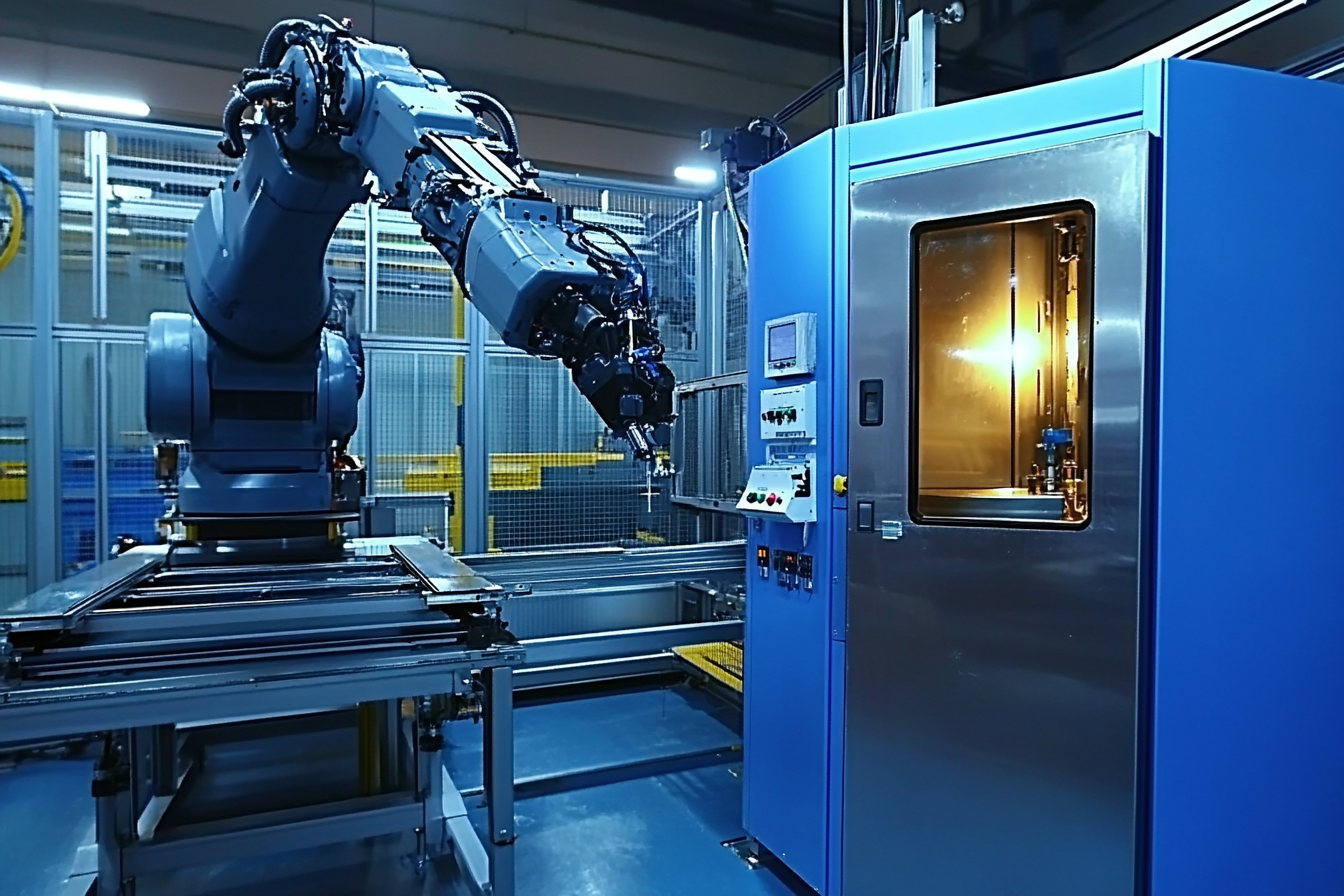

Modern Rubber Products delivers specialized sealing components engineered for the demanding requirements of appliance manufacturing. Our precision-manufactured gaskets, seals, and custom rubber components are designed to withstand temperature variations, operational vibration, and the diverse operating environments encountered in household and commercial appliances. We provide reliable rubber solutions for refrigeration equipment, laundry machines, dishwashers, cooking appliances, and HVAC systems that ensure proper operation while enhancing energy efficiency and consumer safety. Our Chattanooga manufacturing facility employs advanced fabrication techniques to create components that maintain integrity throughout years of consumer use while meeting the exacting tolerances required for modern appliance design.

Critical Appliance Manufacturing Applications

Our rubber components serve essential functions throughout consumer and commercial appliances, including:

- Door seals and gaskets for refrigerators and ovens

- Water inlet and drain pump seals for dishwashers

- Vibration isolation mounts for motors and compressors

- Washer and dryer door boots and tub seals

- Air circulation system gaskets and dampers

- Control panel and interface seals

- Water dispenser and ice maker components

- Custom molded seals for specialized appliance designs

Rubber Engineered for Consumer Product Performance

Modern Rubber Products manufactures a comprehensive range of sealing solutions specifically designed for appliance requirements. Our components are produced using materials selected for their documented performance in residential and commercial applications. We utilize advanced elastomers including EPDM, silicone, NBR, and specialized compounds formulated to withstand cleaning chemicals, food contact, and the temperature extremes found in modern appliances. Our engineering team ensures each component meets OEM specifications while delivering reliable performance throughout the intended product lifecycle.

Meeting the Unique Challenges of Appliance Design

Appliance applications present unique demands for rubber components, requiring materials and designs that ensure both reliable performance and consumer safety. At Modern Rubber Products, we understand these specialized needs:

Material Selection for Application-Specific Requirements

Appliance manufacturing involves diverse requirements for elastomer components. Our appliance industry products are manufactured using compounds specifically formulated to provide:

- Food-safe materials for refrigeration and food preparation appliances

- Temperature resistance for cooking and heating applications

- Water and steam resistance for laundry and dishwashing equipment

- Chemical resistance to cleaning agents and detergents

- Low compression set for maintained sealing during cyclic operation

- UL-recognized materials for electrical safety compliance

- Energy-efficient sealing for improved appliance performance

Precision Manufacturing for Consumer Products

Appliance components must provide reliable sealing while fitting precisely into complex assemblies. Our manufacturing capabilities, including compression molding, injection molding, and die cutting, produce components with exact specifications and tolerances required for proper installation in modern high-efficiency appliances with tight dimensional requirements.

Quality Testing for Consumer Durability

Appliance reliability depends on component performance. Our quality assurance processes include:

- Temperature cycling for thermal stability verification

- Compression set testing for long-term sealing

- Cleaning agent compatibility testing

- Tensile and elongation testing to ASTM standards

- Custom testing protocols for specialized applications

- Life cycle testing for predicted durability

Specialized Solutions for Smart Appliances

Modern Rubber Products supports the evolution of appliance technology with specialized components designed for the emerging smart appliance sector. Our smart appliance offerings include:

- Water-resistant sealing systems for electronic interfaces

- Specialized gaskets for integrated display panels

- Custom-designed seals for sensor integration

- Vibration isolation for quieter, smart-enabled operation

- EMI/RFI shielding gaskets for electronic protection

Appliance Manufacturing Industry FAQs

What rubber materials are best suited for refrigerator door gaskets?

For refrigerator door gaskets, we typically recommend specialized PVC compounds and certain EPDM formulations specifically designed for low-temperature flexibility and compression set resistance. These materials maintain their sealing properties despite thousands of opening and closing cycles while providing excellent thermal insulation properties. For commercial refrigeration applications, we offer magnetic gasket systems with specialized rubber compounds that optimize energy efficiency while meeting NSF requirements.

How do your products help improve appliance energy efficiency?

Our engineered sealing solutions directly contribute to appliance energy efficiency through precision-designed gaskets that minimize air and moisture exchange. For refrigeration applications, our door gaskets provide superior thermal barriers that reduce energy consumption, while our HVAC appliance seals optimize airflow control. We work with appliance designers to develop sealing solutions that contribute to energy efficiency ratings while maintaining reliable operation throughout the appliance lifecycle.

Can you provide custom door seals for washing machines and dryers?

Yes, we specialize in manufacturing door boots and seals for laundry appliances, including front-loading washers, dryers, and combination units. Our custom-designed seals incorporate specialized features such as anti-microbial additives to prevent mold growth, drainage channels to prevent water pooling, and reinforced mounting areas for long-term durability. We work closely with appliance manufacturers to develop sealing solutions that optimize both performance and consumer satisfaction.